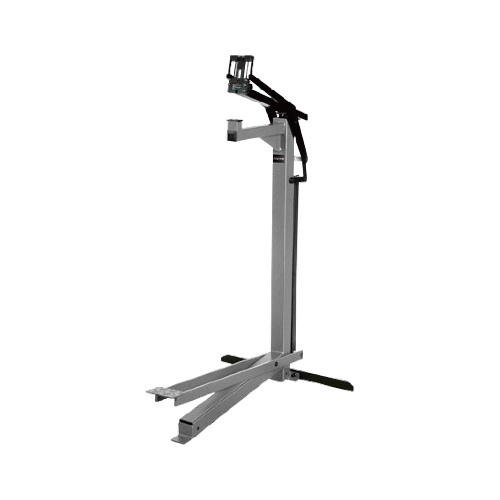

Manual Side Bottomer

FSB743718

Foot Operated Side Bottomer- Specification

- L x W x H: 910 x 600 x 1245 mm

- Weight: 24.6 kgs

- Working Height: 950 mm

- Throat Depth: 320 mm

- Loading Capacity: 200 pcs

Description

- Staple Type: Carton Closing Staples

- Crown: 34.5 mm

- Width x Thickness: 0.9 x 1.9 mm

- Fastener Range: 15, 18 mm

- Select the staples for FSB743718

Product Overview

The FSB743718 Foot Operated Side Bottomer is a robust and efficient tool designed to meet the demands of manual side stapling in dynamic packing environments. Featuring a 34.5 mm crown and compatibility with 15 mm and 18 mm fasteners, it offers focused performance for specific carton reinforcement needs without unnecessary complexity. With a working height of 950 mm and a throat depth of 320 mm, the FSB743718 ensures ergonomic access and reliable vertical stapling, even in workspaces where box sizes vary and automation is limited. Operators benefit from precise foot-activated control, enabling secure and consistent fastening across diverse packaging tasks.

Constructed with a solid steel frame and operating without the need for electricity or air supply, the FSB743718 is built for mobility and long-term durability. Its straightforward setup and reliable stapling performance make it a strategic choice for facilities seeking a specialized, operator-friendly solution to enhance load security during handling and storage.

Application

- Manual stapling of carton side flaps to reinforce tall or heavy boxes.

- Applied in workspaces with irregular box sizes or limited automation.

- Ideal for occasional side stapling tasks during packing or repacking.

- Supports specialized projects or packaging where vertical sealing is required.

Features

- Hand-lever or foot-controlled operation allows precise manual stapling.

- Strong steel structure designed for repeated side stapling use.

- No need for power or air — easy to move between stations.

- Straightforward setup and usage for flexible packaging lines.

- Helps increase load stability for transport or storage.

Comparison Chart for Similar Products

| Foot Operated Side Bottomer | |||||||

|---|---|---|---|---|---|---|---|

| Model No. |

Working Height |

Throat Depth |

Stapler Crown |

Width x Thickness |

Fastener Range | L x W x H | Weight |

| FSB3522S | 950 mm | 320 mm | 34.7 mm | 0.9 x 2.3 mm | 15, 18, 22 mm | 910 x 600 x 1245 mm |

24.6 kg |

| FSB3422 | 34 mm | 0.9 x 2.3 mm | 16, 19, 22 mm | ||||

| FSB3222 | 32 mm | 0.9 x 1.9 mm | 15, 18, 22 mm | ||||

| FSB743718 | 34.5 mm | 0.9 x 1.9 mm | 15, 18 mm | ||||

| FSB904022 | 34.5 mm | 0.9 x 2.3 mm | 15, 18, 22 mm | ||||

| FSB1618 | 16 mm | 0.6 x 1.8 mm | 8, 12, 15, 18 mm | ||||

| HFSB3522 | 1085 mm | 394 mm | 34.7 mm | 0.9 x 2.3 mm | 15, 18, 22 mm | 979 x 732 x 1315 mm |

44.26 kg |

| HFSB3222 | 32 mm | 0.9 x 1.9 mm | 15, 18, 22 mm | ||||

| HFSB5315 | 14.8 mm | 0.6 x 1.3 mm | 6, 9, 12, 15 mm | 930 x 732 x 1315 mm |

|||

| MSB1656 | 1115 mm | 559 mm | 16 mm | 0.59 x 1.8 mm | 8, 12, 15, 18 mm | 945 x 732 x 1291 mm |

52.6 kg |

| MSB1676 | 1153 mm | 759 mm | 990 x 732 x 1328 mm |

70.4 kg | |||

FAQ

1. How to select the most suitable foot-operated side bottomer for your needs?

Selecting the most suitable foot-operated side bottomer involves evaluating several critical factors based on your specific application. First, consider the throat depth and working height to ensure the machine can accommodate the size and thickness of your workpieces while providing comfortable operation for the user. Next, verify the staple specifications the machine supports, including the crown width, leg length, and gauge, to match the fastening requirements of your materials. Additionally, determine whether you need a manual-only model or a pneumatic-assisted model; manual models are ideal for locations without access to air compressors or electricity, while pneumatic models reduce operator fatigue and enhance production speed in high-volume environments.

Understanding the type of material you are fastening is also essential, as different materials (such as cardboard, wood, or plastics) may require specific staple penetration strength or machine adjustments. Your production volume will further influence the decision—low to medium production volumes can rely on manual models, whereas high-volume operations may benefit from pneumatic options for increased efficiency. Finally, ergonomic considerations such as adjustable working height and foot pedal sensitivity should not be overlooked, as these features contribute to operator comfort, prevent long-term strain, and enhance overall productivity.

2. What are the advantages of manual foot-operated side bottomers?

Manual foot-operated side bottomers offer several key advantages:

- Ease of Operation: Simple mechanical design allows easy use without complex setup.

- No Need for Air Compressor or Electricity: Ideal for locations where power sources are limited or mobility is critical.

- Hands-Free Operation: Foot pedal activation frees both hands to position materials precisely, improving efficiency and safety.

- Cost Efficiency: Lower upfront investment and minimal maintenance costs compared to pneumatic or electric models.

- Portability: Lightweight and compact for easy relocation within production facilities or workshops.

- Durability: Built with robust mechanical structures for long service life with minimal maintenance.

3. What are foot-operated bottomers and side bottomers? How do they differ?

Foot-operated bottomers are designed for stapling the bottom flaps of corrugated cartons and are commonly used in floor-standing operations. Side bottomers, on the other hand, are specialized for fastening the vertical sides of cartons, reinforcing the structural integrity of packages. Choosing between the two depends on whether your packaging process primarily requires bottom closure or side reinforcement.

OEM service

Our OEM services offer comprehensive customization options to meet your specific branding needs. We provide the ability to customize the color of your nail gun, apply your private label, design and create personalized packaging, and manual.

With our OEM services, you can confidently create a unique and professional product line that stands out in the market.

Guarantee

VIM warrants to the original purchaser that our nailer will be free from defects in material and workmanship under normal use for a period of 1 year from the date of original purchase.

If this nailer should prove to be defective in material or workmanship within the warranty period, we will send the spare parts to you to replace, without charge.

The 1-year warranty does not include easy-worn parts, and any defect or damages caused by resulting from accident, misuse, abuse, improper maintenance, or normal wear and tear.

Shipping Information

VIM offers a variety of shipping options to ensure your order reaches you in the most economic, convenient and timely manner. Below are the available shipping methods.

Please select your preferred shipping method during checkout. If you have any questions or needs, feel free to contact us.

Express Shipping

For expedited delivery, we provide express shipping through the following carriers: UPS, FedEx, DHL, OCS, SF Express, etc.

.png)

Sea Freight

For larger and less urgent shipments, we offer sea freight services. This cost-effective method is ideal for bulk orders and items that do not require immediate delivery.

Air Freight

If you need a balance between speed and cost, air freight will be your option. It is faster than sea freight and suitable for medium to large shipments that need to arrive quickly.