Safety Starts Here: Explore 5 Smart Safety Designs in Pneumatic Nailers and Staplers

In high-pressure work environments such as construction sites, furniture production lines, and professional repair shops, safety is not a luxury—it’s a necessity. Pneumatic nailers and staplers are powerful tools that greatly improve fastening efficiency, but without proper safeguards, they can pose significant risks. Issues like accidental firing, recoil injuries, and internal wear can arise from inadequate design or improper handling. That’s why understanding and implementing effective nailer safety and staple gun safety measures is essential for anyone working with these tools.

This article explores the safety-critical design features built into modern pneumatic fastening tools and provides practical guidelines to enhance both nailer safety and stapler safety. From CE-certified mechanisms to daily usage precautions, every detail plays a role in protecting users and maintaining long-term tool performance. Whether you're a procurement manager sourcing industrial-grade equipment or a technician handling tools on the ground, investing in the right safety solutions is key to safer, more productive operations.

Why Safety Design Matters in Pneumatic Nailers/Staplers

For industrial users and professional repair technicians, safety is not optional—it’s a prerequisite. Pneumatic nailers and staplers operate under high-pressure air, and even minor design flaws can result in serious injuries or costly downtime. During fastening operations, certain air nailers and staplers may generate flying debris or exert strong recoil forces. If misfired, these tools can cause severe harm to operators or nearby personnel. Without proper safety mechanisms, a single misfire can lead to severe consequences for both the operator and those nearby. This highlights the critical importance of nail gun safety and staple gun safety in daily operations.

For industrial users and professional repair technicians, safety is not optional—it’s a prerequisite. Pneumatic nailers and staplers operate under high-pressure air, and even minor design flaws can result in serious injuries or costly downtime. During fastening operations, certain air nailers and staplers may generate flying debris or exert strong recoil forces. If misfired, these tools can cause severe harm to operators or nearby personnel. Without proper safety mechanisms, a single misfire can lead to severe consequences for both the operator and those nearby. This highlights the critical importance of nail gun safety and staple gun safety in daily operations.

Safety-oriented design features play a pivotal role in preventing accidents and enhancing user control. Selecting the appropriate safety configuration based on the tool model, application, and jobsite environment is vital. Whether you're using a coil nailer for framing or a crown stapler for insulation, nailer safety and staple gun safety should always be a top consideration.

For procurement specialists and importers, choosing pneumatic nailers and staplers with certified safety systems goes far beyond meeting CE regulatory requirements. It ensures reliability and peace of mind across varied working conditions. A thoughtfully engineered safety system not only prevents incidents but also supports long-term productivity, especially in high-frequency or heavy-duty applications. In today's competitive landscape, investing in tools that prioritize nail gun safety and stapler safety is a strategic decision that protects both personnel and business operations.

5 Nailer and Stapler Safety Designs

Modern pneumatic nailers and staplers incorporate multiple safety mechanisms to reduce workplace injuries and ensure precise control during operation. Below are five commonly adopted nail gun and stapler safety designs that users should consider when selecting fastening tools for industrial or professional use.

Double Trigger (Safety Trigger)

The double trigger system, also known as the safety trigger, requires two distinct actions before a fastener is released: the user must first press the safety trigger, followed by the main trigger. This design helps prevent accidental firing caused by unintentional contact with the main trigger. It is especially valuable in environments where frequent repositioning of the tool increases the risk of misfires.

The double trigger system, also known as the safety trigger, requires two distinct actions before a fastener is released: the user must first press the safety trigger, followed by the main trigger. This design helps prevent accidental firing caused by unintentional contact with the main trigger. It is especially valuable in environments where frequent repositioning of the tool increases the risk of misfires.

Extended reading: Air Nailer Troubles? 6 Trigger Issues and How to Fix Them

Contact Safety Lever

Also known as a contact trip or nose safety, the contact safety lever must be fully depressed against the material before the tool can actuate. This feature ensures that the nail or staple is only driven when the tool is positioned correctly. It adds an extra layer of security and helps operators maintain control when moving between fastening points.

Also known as a contact trip or nose safety, the contact safety lever must be fully depressed against the material before the tool can actuate. This feature ensures that the nail or staple is only driven when the tool is positioned correctly. It adds an extra layer of security and helps operators maintain control when moving between fastening points.

Sequential Firing

Sequential firing mode requires the contact safety lever to be pressed against the work surface before the trigger can be pulled to fire a fastener. This ensures that the tool is in proper position prior to actuation, significantly reducing the likelihood of double-firing or accidental discharge. This design is ideal for precision applications or when working in tight spaces where control is critical.

Sequential firing mode requires the contact safety lever to be pressed against the work surface before the trigger can be pulled to fire a fastener. This ensures that the tool is in proper position prior to actuation, significantly reducing the likelihood of double-firing or accidental discharge. This design is ideal for precision applications or when working in tight spaces where control is critical.

Related reading: The All-in-One Reference for 4 Firing Modes in Pneumatic Tools

Anti-dry Fire Design

The anti-dry fire mechanism prevents the tool from firing when the magazine is nearly empty or completely out of fasteners. This feature protects both the tool and the work surface from damage due to blank shots, while also enhancing operator safety. Anti-dry fire systems can extend tool lifespan and reduce unnecessary maintenance caused by internal wear.

The anti-dry fire mechanism prevents the tool from firing when the magazine is nearly empty or completely out of fasteners. This feature protects both the tool and the work surface from damage due to blank shots, while also enhancing operator safety. Anti-dry fire systems can extend tool lifespan and reduce unnecessary maintenance caused by internal wear.

This nail gun safety design is commonly found in pin nailers, which use very fine nails that are difficult to detect visually when running low. The anti-dry fire feature helps ensure consistent performance and prevents invisible misfires, especially in delicate finish work where surface integrity is critical.

Related reading: The Ultimate Guide to Pin Nailers: How to Pick the Best One for Any Job

Exhaust Deflector

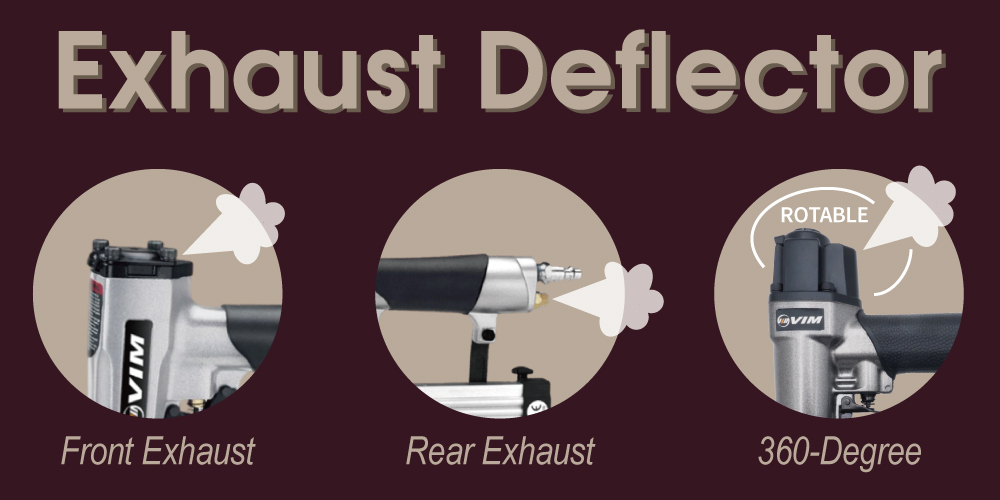

The exhaust deflector directs the flow of discharged air away from the operator’s face and hands. In high-volume applications, especially when using compressed air tools continuously, proper exhaust management reduces fatigue and exposure to airborne dust or debris. There are three common exhaust designs used in pneumatic tools for nail gun safety and stapler safety:

The exhaust deflector directs the flow of discharged air away from the operator’s face and hands. In high-volume applications, especially when using compressed air tools continuously, proper exhaust management reduces fatigue and exposure to airborne dust or debris. There are three common exhaust designs used in pneumatic tools for nail gun safety and stapler safety:

- Front exhaust

Channels the exhaust air out through the front of the tool, helping to clear dust and debris from the fastening area. This can improve visibility but may also stir up particles toward the work surface, making it more suitable for outdoor or rough environments. - Rear exhaust

Directs the air away from the workpiece and toward the rear, minimizing disruption to the immediate working area. This is ideal for finish work or indoor use, where maintaining a clean surface is essential. - 360-degree adjustable exhaust

Allow the operator to manually rotate the exhaust port in any direction. This flexible design enhances user comfort by letting them direct the airflow away from their body regardless of tool orientation, making it particularly useful in tight or awkward positions.

Precautions for Using Pneumatic Nailers/Staplers

To ensure nailer safety, staple gun safety, and efficient operation of pneumatic tools, users must follow essential precautions. These tools operate under high-pressure air and can pose serious risks if mishandled.

To ensure nailer safety, staple gun safety, and efficient operation of pneumatic tools, users must follow essential precautions. These tools operate under high-pressure air and can pose serious risks if mishandled.

Below are key safety considerations for your reference. By incorporating these nail gun and stapler safety practices into daily operations, users can significantly reduce the risk of accidents and extend the lifespan of their pneumatic tools.

Inspect Before Use

Always check the tool for signs of wear, air leaks, or loose parts before each use. Ensure that the air hose and connectors are secure and in good condition. Damaged components can lead to misfiring or reduced control.

Perform Regular Maintenance and Cleaning

Routine maintenance plays a crucial role in ensuring both performance and operator safety. Dust, oil buildup, and jobsite debris can compromise the tool’s firing accuracy and disable essential safety mechanisms, increasing the risk of accidental discharge or tool malfunction. To uphold nail gun safety and staple gun safety, it’s essential to follow the manufacturer’s recommended service intervals—this includes regular lubrication of internal components, clearing exhaust ports, and inspecting trigger assemblies. For both nailer safety and stapler safety, consistent upkeep not only extends the lifespan of the tool but also safeguards users during high-frequency or precision-demanding applications.

Replace Easy-Wear Spare Parts Regularly

Certain components such as O-rings, driver blades, bumpers, and seals are subject to wear from frequent use. Replacing these parts at regular intervals can prevent unexpected breakdowns, maintain consistent driving force, and enhance long-term tool reliability.

Related reading: Beyond OEM: 6 Reasons Why More Distributors Are Switching to Aftermarket Bumpers

Related reading: 6 Truths About Aftermarket Air Stapler Parts and Air Nailer Parts

Disconnect Air Supply When Not in Use

To maintain proper nail gun safety and staple gun safety, always disconnect the air supply before loading fasteners, making adjustments, or performing maintenance. This precaution prevents accidental firing and supports overall nailer safety and stapler safety by eliminating internal pressure that could trigger unintentional discharge.

Use the Correct Fasteners

Only use fasteners that are compatible with the tool’s specifications. Using the wrong size or type can cause jamming, misfires, or damage to the internal components.

Wear Appropriate Equipment

Operators should wear safety glasses, hearing protection, and gloves when using pneumatic tools. This minimizes the risk of injury from flying debris, noise exposure, or accidental tool contact.

Avoid Pointing the Tool at Yourself or Others

Always treat the tool as if it is loaded. Never point it toward people, even when disconnected, and avoid resting your hand or body near the firing zone during operation.

Engineered for Safety: Nailers and Staplers You Can Trust

At VIM, Nail Gun Safety and Staple Gun Safety are fundamental principles in our product development. All of our pneumatic nailers and staplers are CE-certified , meeting international standards to ensure user protection and operational reliability. Whether it’s a construction site or a furniture workshop, we know that every shot fired must be safe, accurate, and controlled.

At VIM, Nail Gun Safety and Staple Gun Safety are fundamental principles in our product development. All of our pneumatic nailers and staplers are CE-certified , meeting international standards to ensure user protection and operational reliability. Whether it’s a construction site or a furniture workshop, we know that every shot fired must be safe, accurate, and controlled.

Take our pin nailers, for example—commonly used in cabinetry or delicate trim work, most of these tools are engineered with a double trigger system and anti-dry fire mechanism. This prevents the tool from firing when nails run out and reduces the chance of accidental discharge, reinforcing best practices in nailer safety.

Our coil nailers, often chosen for pallet assembly or fencing, feature a 360-degree rotatable exhaust design. This allows professionals to redirect the airflow away from their face or workspace, enhancing comfort and operational control. It’s a thoughtful detail that supports both nail gun safety and ergonomic efficiency in demanding environments.

When it comes to narrow crown staplers and wide crown staplers, precision and safety go hand in hand. Most of these models are equipped with sequential firing mode, a feature that requires users to follow a deliberate trigger sequence—perfect for preventing unintended shots during high-speed stapling tasks. It’s one of many ways we integrate stapler safety into tools designed for packaging, insulation, and paneling work.

Across the board, VIM combines innovation and user protection to deliver fastening tools that professionals can rely on—tools that don’t just get the job done but do so with built-in peace of mind.

Conclusion

Nailers and staplers are indispensable in many industries, but they demand a deep respect for safety. By prioritizing features such as double triggers, anti-dry fire systems, sequential firing modes, and adjustable exhaust deflectors, both manufacturers and users can significantly reduce the risk of injury and operational downtime. More importantly, adopting proper handling habits—like disconnecting the air supply before maintenance and performing regular tool inspections—further reinforces nail gun safety and staple gun safety in everyday practice.

At VIM, we believe that reliable performance begins with responsible design. Our pneumatic tools are built not only to deliver power and precision but also to meet the highest standards of nailer safety and stapler safety. Whether on the factory floor or in the field, choosing tools with advanced safety systems is a long-term investment in your team’s protection and productivity. After all, safe fastening is smart fastening.

Looking for CE-certified pneumatic tools that prioritize safety and performance? Contact us to learn more about our full range of nailers, staplers, and pliers designed with your safety in mind.

Article Classification

Recent Articles

- Avoid Costly Jams: 5 Proven Hog Ring Plier Repair Solutions that Work

- 4 Simple Ways to Maintain Your Hog Ring Plier for Better Performance

- Narrow vs Wide Crown Stapler: 3 Steps to Make the Right Choice

- Safety Starts Here: Explore 5 Smart Safety Designs in Pneumatic Nailers and Staplers

- Handheld vs. Foot-Operated Carton Staplers: Which Is Better for Your Workflow?