Pneumatic Bottomer

PB904022

Pneumatic Bottomer- Specification

- L x W x H: 830 x 600 x 1245 mm

- Weight: 29.3 kgs

- Working Height: 950 mm

- Throat Depth: 320 mm

- Loading Capacity: 200 pcs

- Operating Pressure: 5.5 - 6 bar (70 - 90 psi)

Description

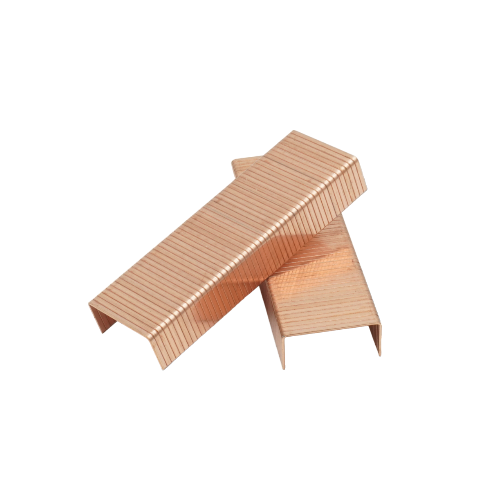

- Staple Type: Carton Closing Staples

- Crown: 34.5 mm

- Width x Thickness: 0.9 x 2.3 mm

- Fastener Range: 15, 18, 22 mm

- Select the staples for PB904022

Product Overview

Designed to handle high-demand packaging environments, the PB904022 Pneumatic Bottom Stapler offers a powerful combination of strength, precision, and versatility. Featuring a 34.5 mm crown and supporting fastener lengths of 15, 18, and 22 mm, the PB904022 is engineered to secure heavy-duty corrugated cartons that require enhanced bottom reinforcement for load stability and safe transport.

With a working height of 950 mm and a throat depth of 320 mm, the PB904022 easily accommodates large-format cartons, making it ideal for industrial-scale packaging operations. Its pneumatic-driven system delivers steady stapling force, and the adjustable air pressure ensures consistent fastening across different carton grades. The foot pedal activation enables ergonomic, hands-free operation, significantly improving productivity and reducing operator strain during continuous production shifts.

Built with an emphasis on durability and efficiency, and equipped with a 200-staple loading capacity, the PB904022 supports uninterrupted workflow and requires minimal maintenance. It is the reliable choice for industrial, agricultural, and export packaging facilities looking for long-term performance and high-throughput capability.

Application

- Bottom stapling of large, heavy-duty, or high-value corrugated cartons.

- Ideal for packaging that requires reinforced bottom closure for added load stability.

- Commonly used in industrial, agricultural, and export packaging operations.

- Suitable for production lines demanding consistent, high-throughput stapling performance.

Features

- Pneumatic-powered system delivers steady and uniform stapling performance.

- Foot pedal activation allows hands-free carton positioning and handling.

- Air pressure can be adjusted to control stapling force based on carton material.

- Smooth and efficient operation reduces operator fatigue in continuous work shifts.

- Durable construction built for industrial environments with minimal maintenance needs.

Comparison Chart for Similar Products

| Pneumatic Bottomer with Foot Pedal | |||||||

|---|---|---|---|---|---|---|---|

| Model No. |

Working Height |

Throat Depth |

Stapler Crown |

Width x Thickness |

Fastener Range | L x W x H | Weight |

| PB3522 | 950 mm | 320 mm | 34.7 mm | 0.9 x 2.3 mm | 15, 18, 22 mm | 830 x 600 x 1245 mm |

29.3 kg |

| PB3422 | 34 mm | 0.9 x 2.3 mm | 16, 19, 22 mm | ||||

| PB3222 | 32 mm | 0.9 x 1.9 mm | 15, 18, 22 mm | ||||

| PB743718 | 34.5 mm | 0.9 x 1.9 mm | 15, 18 mm | ||||

| PB904022 | 34.5 mm | 0.9 x 2.3 mm | 15, 18, 22 mm | ||||

| PB1618 | 16 mm | 0.6 x 1.8 mm | 8, 12, 15, 18 mm | ||||

| HPB3522 | 1085 mm | 394 mm | 34.7 mm | 0.9 x 2.3 mm | 15, 18, 22 mm | 985 x 732 x 1360 mm |

46.33 kg |

| HPB3222 | 32 mm | 0.9 x 1.9 mm | 15, 18, 22 mm | ||||

| HPB5315 | 14.8 mm | 0.6 x 1.3 mm | 6, 9, 12, 15 mm | ||||

FAQ

1. What is the difference between manual and pneumatic bottomers?

The key difference lies in the power source and operating method. Manual bottomers rely on physical force from the operator, making them ideal for low- to medium-volume applications.

Pneumatic bottomers, on the other hand, are powered by compressed air, offering faster, more consistent stapling performance and greatly reducing operator fatigue — an advantage for high-volume production lines.

2. What are foot-operated bottomers and side bottomers? How do they differ?

Foot-operated bottomers are designed for stapling the bottom flaps of corrugated cartons and are commonly used in floor-standing operations. Side bottomers, on the other hand, are specialized for fastening the vertical sides of cartons, reinforcing the structural integrity of packages. Choosing between the two depends on whether your packaging process primarily requires bottom closure or side reinforcement.

3. How do I choose the right foot-operated bottomer?

When selecting a foot-operated bottomer, consider the working height and throat depth to ensure they match your carton sizes. It's also critical to check the specifications of the carton closing staples—such as crown width and fastener length—to guarantee secure and reliable fastening.

In terms of operation type, manual foot-operated bottomers are suitable for small to medium production runs, while pneumatic models are ideal for high-volume, continuous workflows. Your final choice should depend on your packaging scale, material characteristics, and production efficiency requirements.

4. How do I operate a pneumatic foot-operated bottomer?

To operate a pneumatic foot-operated bottomer:

- Connect the air supply: Attach the machine to a reliable compressed air source. Adjust the air pressure according to the thickness and type of carton you are sealing; the pressure settings should follow the recommendations provided in the manual to ensure proper stapling performance and equipment safety.

- Load the staples: Open the magazine and insert the appropriate staples specified for your bottomer model.

- Position the carton: Place the carton properly on the worktable to align the stapling point.

- Activate the stapling mechanism: Step firmly on the foot pedal to drive the staple and secure the carton.

Always ensure the air pressure is stable and conduct periodic maintenance to keep the equipment running smoothly.

OEM service

Our OEM services offer comprehensive customization options to meet your specific branding needs. We provide the ability to customize the color of your nail gun, apply your private label, design and create personalized packaging, and manual.

With our OEM services, you can confidently create a unique and professional product line that stands out in the market.

Guarantee

VIM warrants to the original purchaser that our nailer will be free from defects in material and workmanship under normal use for a period of 1 year from the date of original purchase.

If this nailer should prove to be defective in material or workmanship within the warranty period, we will send the spare parts to you to replace, without charge.

The 1-year warranty does not include easy-worn parts, and any defect or damages caused by resulting from accident, misuse, abuse, improper maintenance, or normal wear and tear.

Shipping Information

VIM offers a variety of shipping options to ensure your order reaches you in the most economic, convenient and timely manner. Below are the available shipping methods.

Please select your preferred shipping method during checkout. If you have any questions or needs, feel free to contact us.

Express Shipping

For expedited delivery, we provide express shipping through the following carriers: UPS, FedEx, DHL, OCS, SF Express, etc.

.png)

Sea Freight

For larger and less urgent shipments, we offer sea freight services. This cost-effective method is ideal for bulk orders and items that do not require immediate delivery.

Air Freight

If you need a balance between speed and cost, air freight will be your option. It is faster than sea freight and suitable for medium to large shipments that need to arrive quickly.