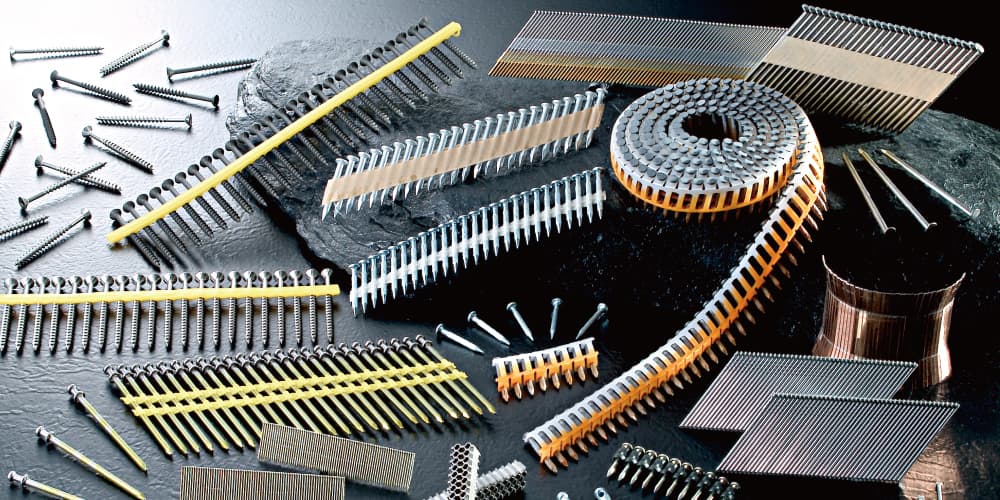

Stop Guessing: 13 Proven Fastener Materials for Choosing the Right Nails and Staples

When selecting the right fastener for any project, understanding the characteristics of different fastener materials is crucial. Each material offers unique advantages in strength, corrosion resistance, weight, and appearance, directly influencing the performance and longevity of staples, nails, and other fastening products. Whether for construction, woodworking, marine applications, or specialized industries, choosing the appropriate fastener material ensures reliable connections and optimized results. This guide explores the most common types of fastener materials and their practical uses across various industries.

【Extended reading: 14 Surface Treatments That Matter: A Closer Look at Fastener Finishing】

Types of Fastener Materials

Low Carbon Steel

Low Carbon Steel

Low carbon steel is one of the most commonly used fastener materials, widely applied in nails, staples, drywall screws, and packaging fasteners. It offers excellent machinability and cost efficiency. Though relatively soft and low in tensile strength, it performs well in dry, non-corrosive environments. Most low carbon steel fasteners require protective coatings to prevent rust and wear.

Used in: General-purpose nails like F and T brads, T-nails, common staples, drywall screws, packaging fasteners.

Medium Carbon Steel

With higher strength and hardness than low carbon steel, medium carbon steel is often used where greater mechanical performance is required. It is commonly selected for nails and staples used in structural and load-bearing applications. It can be heat-treated to improve toughness and fatigue resistance, making it suitable for demanding environments.

Used in: Structural screws, heavy-duty staples.

High Carbon Steel

High carbon steel provides superior hardness and wear resistance among fastener materials. It is well-suited for manufacturing hardened nails and industrial staples where high strength and durability are critical. Heat treatment enhances its hardness, though protective coatings are recommended to prevent corrosion.

Used in: Masonry nails, heavy-duty fasteners like ST and FST nails, industrial staples.

Alloy Steel

Alloy steel fasteners are engineered for high tensile strength, wear resistance, and fatigue resistance. By combining carbon steel with alloying elements like chromium, molybdenum, or vanadium, they perform exceptionally well under extreme load or vibration. Alloy steel is also used in specialized nails requiring enhanced mechanical properties. However, it is more prone to corrosion and typically requires protective coatings.

Used in: Concrete nails, Framing nails, high-strength bolts, industrial-grade screws, automotive fasteners.

Stainless Steel

Highly resistant to rust and chemical corrosion, stainless steel is an ideal fastener material for both interior and exterior environments, including marine and food-grade applications. It is primarily used for nails and staples in outdoor, marine, and high-humidity environments, and occasionally in specialized food processing applications. Common grades include 304 (general corrosion resistance), 316 (superior marine resistance), and 410 (hardenable with good strength and wear properties).

Used in: Brad nails, finish nails, coil nails, pin nails, fencing staples, C-rings for food packaging, exterior screws, marine fasteners.

Aluminum

Aluminum is a lightweight, corrosion-resistant, and non-magnetic option among Fastener Materials, making it ideal for applications where reducing weight is a priority. This material is commonly used to manufacture Staples and Nails designed for light-duty or decorative purposes. While aluminum fasteners offer ease of use and resistance to rust, they are not recommended for high-load or structural applications.

Used in: Office staples, bag sealing staples, fine wire staples, loose nails, decorative nails.

Brass

Brass is valued as a fastener material for its distinctive gold-like appearance and corrosion resistance. It is commonly used in decorative nails, furniture tacks, and brass screws where aesthetics and function are both important. Its non-sparking properties also lend it unique industrial uses.

Used in: Decorative nails, 15 and 16 gauge furniture staples, office staples, screws for musical instruments or electronics.

Copper

Soft, conductive, and corrosion-resistant, copper is a specialized fastener material used in certain staples for electronics and nails for roofing or flashing. While not ideal for high-strength fastening, it is valued for its electrical conductivity and antimicrobial properties.

Used in: Carton closing staples, upholstery staples, office staples, roofing nails, slating nails, decorative nails.

Silicon Bronze

Silicon bronze is a premium fastener material known for its excellent corrosion resistance, strength, and distinctive reddish-brown color. Made primarily from copper with silicon and small amounts of other alloys, it offers superior durability in marine, high-moisture, and corrosive environments. While not as widely used as steel, silicon bronze fasteners are valued for their longevity and aesthetic appeal in applications such as boatbuilding, timber framing, and exterior construction. Silicon bronze nails and staples are often chosen for their combination of mechanical strength and resistance to saltwater corrosion.

Used in: Marine fasteners, timber framing nails, bolts and nuts.

Titanium

Titanium is an exceptional choice among fastener materials, offering a unique combination of extreme strength, light weight, and superior corrosion resistance. While titanium fasteners are rarely used in general-purpose staples or nails, they are highly valued in medical and aerospace applications where biocompatibility, durability, and weight reduction are critical.

Used in: Surgical staples, implants, bone screws, aerospace screws and bolts, marine hardware.

Bi-Metal

Bi-metal fasteners combine two metals to achieve a balance of corrosion resistance, strength, and cost-efficiency. A common example is a screw with a stainless steel shank fused to a hardened carbon steel tip, providing both corrosion resistance and drilling capability. This material combination is widely used in screws and fasteners designed to join dissimilar materials or for applications requiring both durability and penetration strength.

Used in: Screws, fasteners for dissimilar material joints.

Plastic and Nylon

Plastic and nylon are versatile non-metallic fastener materials offering corrosion resistance, non-conductivity, and a lightweight profile. These materials are used for staples and nails in applications where metal fasteners may corrode, conduct electricity, or interfere with metal detection. Plastic fasteners, including F brads, T brads, and certain staples, can also be driven into wood, providing a non-corrosive, non-marring alternative for wood fastening, furniture assembly, and other specialized uses. While not intended for heavy structural loads, they deliver sufficient holding power for many industrial, marine, and electrical applications.

Used in: F brads, T brads, staples, marine staples, Cable clips, furniture screws, electronics hardware.

Wood

Wood is one of the oldest Fastener Materials, offering a lightweight, non-metallic solution for joining wood components. Although less common in modern structural applications, wooden Nails remain in use for specialized purposes such as furniture making, timber framing, and traditional woodworking. Loose Nails and coil Nails made from wood provide a corrosion-free fastening option that blends naturally with wood substrates while eliminating the risk of metal staining in high-moisture environments. Wooden fasteners are also used as trunnels and treenails in heritage construction and restoration projects.

Used in: loose Nails, plastic collated coil Nails, timber framing, furniture making, trunnels, treenails for boatbuilding.

Conclusion

Selecting the right fastener material is more than just choosing between metal and non-metal—it’s a critical decision that influences durability, corrosion resistance, mechanical strength, and long-term performance. From low carbon steel staples in packaging to silicon bronze nails in marine construction, each material offers unique properties tailored to specific environments and applications. By understanding the strengths and limitations of different fastener materials, manufacturers, builders, and end users can ensure their nails and staples deliver reliable performance while meeting safety, aesthetic, and environmental requirements.

Selecting the right fastener material is more than just choosing between metal and non-metal—it’s a critical decision that influences durability, corrosion resistance, mechanical strength, and long-term performance. From low carbon steel staples in packaging to silicon bronze nails in marine construction, each material offers unique properties tailored to specific environments and applications. By understanding the strengths and limitations of different fastener materials, manufacturers, builders, and end users can ensure their nails and staples deliver reliable performance while meeting safety, aesthetic, and environmental requirements.

At VIM International Enterprise, we specialize in providing high-quality nails and staples crafted from a diverse range of fastener materials to meet the demands of various industries. Whether you need corrosion-resistant staples for marine environments or decorative nails for furniture applications, we are committed to helping you select the ideal product for your specific needs. Contact us to learn more about our product range and tailored solutions for your business.

Article Classification

Recent Articles

- 5 Essential Checklist for Choosing Appropriate Flooring Nails

- Every Corrugated Fastener You Want—All Here in One Comprehensive Guide

- The 4 Carton Staples Issues Ruining Your Packaging—Solved in Minutes

- 5 Reasons Why VIM Concrete T Nails Deliver Unmatched Grip and Durability

- The Hidden Force in Every Staple: 9 Point Types That Make Fastening Last