Why Finishing Matters More Than You Think: 4 Mistakes to Avoid in Fastener Coating Selection

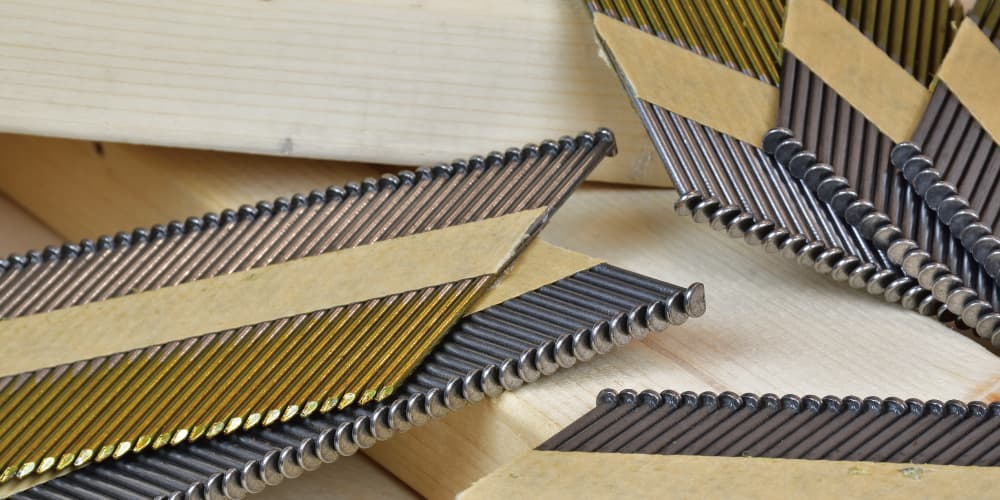

In any construction or manufacturing process, choosing the right fastener coating is not just a technical checkbox—it’s a critical decision that affects product longevity, safety, and compliance. Whether you're working on nails finishing, staples finishing, or screw finishing, the selected coating must withstand the unique environmental, structural, and chemical conditions of the application.

Unfortunately, many professionals still underestimate the importance of finishing. Misjudgments—such as using decorative coatings in load-bearing joints or applying zinc-plated fasteners in alkaline concrete—can compromise the very integrity of a structure. As regulations tighten and performance demands rise, understanding how to match fastener coatings to the right substrates and environments is now essential—not optional.

This guide explores the key factors in coating selection, common industry mistakes, and real-world failure cases that underscore just how costly a mismatched finishing can be.

Choosing the Right Finish for Your Application

When selecting a fastener coating for any Nails Finishing, Staples Finishing, or Screw Finishing task, consider the following:

When selecting a fastener coating for any Nails Finishing, Staples Finishing, or Screw Finishing task, consider the following:

1. Application Environment

- Indoor / Dry Conditions:

Opt for a bright finish, which offers a clean, untreated surface ideal for interior use where corrosion exposure is minimal. - Outdoor / Moist Environments:

Use hot-dip galvanized coating, which creates a thick, durable zinc layer to protect against rust and weather. This coating is well-suited for structural framing, fencing, and decking. - Moderate Outdoor Use:

Electrogalvanized finishes provide a smooth, uniform zinc layer. While they offer some corrosion resistance, they’re best for light exterior or sheltered environments. - High-Corrosion Zones (e.g., coastal, industrial):

Advanced fastener coating options like ceramic coated, zinc flake coating, or vinyl coated finishes ensure superior protection.

2. Material Compatibility & Functional Requirements

- Prevent Reactions or Staining:

For example, use copper-plated staples in carton sealing to avoid corrosion marks or discoloration. In pressure-treated wood, opt for vinyl-coated or mechanical plated fasteners to prevent chemical reactions. - Electrical Conductivity:

Applications requiring electrical connection (such as grounding points or electronic housings) should use gold-plated or copper-coated fasteners for reliable conductivity. - Thermal Resistance:

For high-heat environments, such as engines or ovens, choose ceramic-coated, zinc flake, or hard chrome plated finishes that maintain performance under elevated temperatures.

Tip: Always verify the compatibility of the fastener coating not only with the material, but also with the operational conditions.

3. Project Visibility and Aesthetics

Where appearance matters, choose a finishing that blends with the surrounding material:

- Resin-coated fasteners are available in color-matched options to reduce visual contrast on siding, roofing, or trim.

- For upscale packaging or exposed decorative joints, gold-plated or black Oxide finishes add a refined look while still offering functional performance.

4. Budget Constraints

Your project scale and lifespan should guide your choice of coating:

- For temporary structures or interior applications, go with cost-effective options like bright finish or phosphate coating.

- For long-term installations or high-exposure environments, invest in premium fastener coatings like ceramic-coated, hot-dip galvanized, or zinc flake for extended performance and reduced maintenance.

5. Load Requirements & Long-Term Performance

For high-load or structural applications, focus on coatings that provide superior bonding and corrosion protection:

- Cement-coated nails offer improved grip in construction and drywall projects.

- Zinc flake or resin coatings deliver added resistance to vibration, moisture, and chemical exposure.

- For staples finishing in furniture or upholstery, mechanical plating ensures non-staining performance and extended life.

【Extended reading: Stop Guessing: 13 Proven Fastener Materials for Choosing the Right Nails and Staples】

Common Mistakes in Finish Selection: What Professionals Should Avoid

Choosing the appropriate finishing for nails, staples, and screws is not merely a cosmetic decision—it’s a critical factor in ensuring structural integrity, corrosion resistance, and long-term performance. However, even experienced professionals can make avoidable mistakes when selecting Nails Finishing, Staples Finishing, Screw Finishing, or the appropriate Fastener Coating. Below, we delve into some of the more nuanced errors that can compromise a build or product.

Choosing the appropriate finishing for nails, staples, and screws is not merely a cosmetic decision—it’s a critical factor in ensuring structural integrity, corrosion resistance, and long-term performance. However, even experienced professionals can make avoidable mistakes when selecting Nails Finishing, Staples Finishing, Screw Finishing, or the appropriate Fastener Coating. Below, we delve into some of the more nuanced errors that can compromise a build or product.

1. Mismatching Finish to Application Environment

A more nuanced but still frequent mistake is selecting a fastener coating based solely on general corrosion resistance without considering mechanical stress or chemical exposure specific to the environment. For example, using mechanical plating on steel fasteners in outdoor metal-to-metal contact can result in premature coating wear due to friction and weathering. Similarly, opting for electrogalvanized finishing in marine or coastal zones, rather than hot-dip galvanized, may lead to accelerated corrosion under salt exposure. Tailoring the finishing to the actual use case—not just moisture presence—is essential for durability.

2. Overlooking Compatibility Between Fastener and Substrate

While it’s common knowledge to avoid galvanic corrosion, professionals sometimes fail to recognize more subtle incompatibilities. A screw finishing with a zinc coating may react adversely with treated lumber containing copper-based preservatives. Such electrochemical mismatches can significantly reduce fastener lifespan and compromise both safety and structural integrity. Selecting the right fastener coating means understanding the interaction between material types—not just the fastener itself.

3. Assuming All Coatings Perform the Same Across Fastener Types

Not all coatings behave identically across different fastener geometries. A coating that adheres effectively to nails may flake or apply unevenly on staples due to surface area differences or application methods. Professionals should not assume universal performance of a fastener coating without verifying product data tailored for Staples Finishing or Screw Finishing specifically.

4. Using Aesthetic-Only Coatings in Structural Applications

Some finishes are designed solely for visual appeal. Applying decorative finishing in structural or load-bearing applications—especially for nails finishing or staples finishing—can result in premature wear, rust breakthrough, or coating delamination under stress. In any industrial or construction setting, performance-rated Fastener Coatings must always be prioritized over aesthetics to ensure long-term durability and safety.

【Extended reading: 14 Surface Treatments That Matter: A Closer Look at Fastener Finishing】

Real-World Failures: When Finishing Mistakes Lead to Catastrophe

The importance of selecting the correct fastener coating and finishing isn’t just theoretical—history has shown that mismatched materials and coatings can lead to severe structural failures. Here are notable aerospace incidents where coating or surface treatment decisions played a contributing role:

The importance of selecting the correct fastener coating and finishing isn’t just theoretical—history has shown that mismatched materials and coatings can lead to severe structural failures. Here are notable aerospace incidents where coating or surface treatment decisions played a contributing role:

1. Aloha Airlines Flight 243 (1988)

A Boeing 737-200 suffered explosive decompression mid-flight over Hawaii due to a fuselage rupture. Investigation revealed that the high-humidity, salt-laden coastal environment had exacerbated corrosion at lap joints, where insufficient anti-corrosion protection around rivets led to structural failure.

Key relevance: This case exemplifies a failure to apply the appropriate corrosion-resistant coating in a harsh marine climate.

2. de Havilland Comet Catastrophic Failures (1954)

The world’s first commercial jetliner suffered a series of fatal in-air breakups due to metal fatigue and structural cracking, particularly at riveted joints and window corners. Analysis indicated that surface treatments and coatings were not adequately designed to withstand repeated pressurization cycles.

Key relevance: Though primarily a design issue, post-event studies suggested that better fatigue-resistant finishing and anti-corrosion treatments might have delayed or mitigated failure.

3. Berkeley Balcony Collapse (2015, USA)

A student apartment balcony in Berkeley, California, collapsed during a late-night gathering, resulting in six deaths and multiple injuries. Investigators found that joist hangers and fasteners within the balcony structure had experienced severe corrosion and fungal decay due to trapped moisture in a sealed wooden cavity. The fasteners used were not adequately protected with hot-dip galvanizing or stainless steel finishing.

Key relevance: This failure highlights the dangers of using inadequate fastener coatings in high-humidity, enclosed environments. Proper corrosion-resistant finishing, such as HDG or stainless steel, could have significantly delayed or prevented structural deterioration.

4. Fremantle Hospital Façade Failure (2009–2014, Australia)

Several buildings in coastal Western Australia, including Fremantle Hospital, experienced dangerous tile detachment incidents. The cause was traced to corrosion in the steel nails and anchors holding the ceramic façade in place. The fasteners used were not suited to the marine climate and lacked the protective coatings necessary to withstand high salt exposure. (Note: In modern façade systems, fasteners such as nails or anchors are often used to secure substructures behind cladding panels. Corrosion of these concealed components can result in surface detachment.)

Key relevance: This incident demonstrates the risks of overlooking environmental factors in fastener coating selection. In high-salinity regions, the absence of HDG, stainless steel, or specialized ceramic coatings can result in premature corrosion and structural failure.

Common Real-World Compatibility Pitfalls

| Scenario | What Goes Wrong | Why It Fails |

|---|---|---|

| Aluminum fasteners in contact with copper fittings | Galvanic corrosion | Electrochemical incompatibility between materials causes the aluminum fastener coating to degrade, accelerating corrosion. |

| Epoxy-coated fasteners used in salt-spray zones | Permeation failure | The coating is not rated for chloride-rich environments; salt and moisture eventually penetrate, leading to substrate corrosion beneath the finishing. |

| Zinc-plated fasteners exposed to high-alkaline environments (e.g., wet concrete, detergents) |

Coating delamination | Alkalinity breaks down the zinc coating, causing blistering and loss of protective finishing on the fastener surface. |

| Industrial-grade coatings used in pressurized aircraft cabins | Stress-induced cracking | The surface finishing lacks fatigue resistance and microcracks develop due to repeated cabin pressure cycles. |

| Phosphate-coated fasteners used outdoors | Rapid rusting | Phosphate coating provides only minimal corrosion resistance and is not intended as a standalone finishing for exterior exposure. |

| Black oxide finishing used in marine or humid environments | Surface corrosion | This type of finishing offers poor moisture protection unless combined with a sealant; fastener coating fails under prolonged humidity. |

| Copper-plated fasteners used on acidic woods (e.g., cedar, oak) |

Staining and corrosion | Tannins in the wood react with the coating, leading to discoloration and weakening of the fastener over time. |

| Mechanical-plated fasteners in high-vibration joints | Abrasion wear | The soft coating wears off quickly under movement; applications like these require a more durable fastener finishing. |

| Hot-dip galvanized fasteners painted without primer | Paint peeling | The zinc layer of the coating causes poor adhesion unless properly treated, leading to flaking of decorative or protective finishing layers. |

| Vinyl-coated staples in high-temperature environments | Melting and fumes | Vinyl coating is heat-sensitive and may degrade or release fumes, compromising the fastener’s performance finishing. |

| Bright-finish nails used in ACQ- or CA-treated lumber | Accelerated corrosion | The lack of protective coating makes them unsuitable for chemically treated woods, resulting in fastener failure and rust bleeding. |

Conclusion: Make Finishing a Strategic Decision, Not an Afterthought

In the world of fasteners, not all finishes are created equal. The right fastener coating can safeguard against corrosion, enhance load performance, improve aesthetics, and reduce lifetime maintenance costs. On the other hand, an ill-suited finishing—no matter how minor it may seem—can lead to early structural failures, costly repairs, or even safety hazards. As illustrated by both industry best practices and high-profile failure cases, coating selection should be grounded in a detailed understanding of the application environment, material interactions, and expected stresses. From bright finishes for interior jobs, to zinc flake and ceramic coatings for harsh outdoor or industrial settings, aligning your finishing strategy with real-world demands is critical.

In the world of fasteners, not all finishes are created equal. The right fastener coating can safeguard against corrosion, enhance load performance, improve aesthetics, and reduce lifetime maintenance costs. On the other hand, an ill-suited finishing—no matter how minor it may seem—can lead to early structural failures, costly repairs, or even safety hazards. As illustrated by both industry best practices and high-profile failure cases, coating selection should be grounded in a detailed understanding of the application environment, material interactions, and expected stresses. From bright finishes for interior jobs, to zinc flake and ceramic coatings for harsh outdoor or industrial settings, aligning your finishing strategy with real-world demands is critical.

Ultimately, smart finishing choices are not just about function—they reflect a commitment to quality, responsibility, and long-term durability. At VIM International, we understand that selecting the right fastener coating isn’t only critical for end-users—it’s also essential for the maintenance and repair professionals who keep tools and systems running. From aftermarket driver assemblies to coating-compatible replacement parts, we support fastener performance from the inside out—matching your equipment with the right materials, finishes, and engineering insight.

Need technical input on coating compatibility or fastener rebuild options?

Get in touch with our team and see how VIM can enhance your sourcing decisions with reliable, field-tested components and flexible supply solutions.

Article Classification

Recent Articles

- 5 Essential Checklist for Choosing Appropriate Flooring Nails

- Every Corrugated Fastener You Want—All Here in One Comprehensive Guide

- The 4 Carton Staples Issues Ruining Your Packaging—Solved in Minutes

- 5 Reasons Why VIM Concrete T Nails Deliver Unmatched Grip and Durability

- The Hidden Force in Every Staple: 9 Point Types That Make Fastening Last