How Proper Air Pressure Safeguards Your Pneumatic Tools and Investment

In any high-performance workshop, pneumatic tools are the workhorses of the trade. But even the best equipment is only as good as the air feeding it. Finding the "sweet spot" for your air pressure—not too high, not too low—is the difference between a tool that lasts for decades and one that ends up in the scrap pile within months.

We’re breaking down how to manage your air compressor pressure to protect your investment and your craftsmanship. From fine-tuning the delicate drive of pin nailers and finishing nailers to mastering the raw power of high-pressure systems, getting your air supply right is the first step toward professional results.

【Learn More: Pneumatic vs. Electric Nailer: How to Choose the Best Option for Your Workflow】

Why is Proper Air Pressure Important for Pneumatic Tools?

Understanding and maintaining the correct air pressure is the foundation of any efficient workshop. Whether you are using a nailer, grinder, or impact wrench, the performance of your equipment is directly tied to the consistency of your air compressor pressure. When the pressure is finely tuned, your tools work for you; when it’s neglected, they work against you.

The Benefits of Optimized Air Pressure

- Consistent Tool Performance

Every pneumatic tool is engineered for a specific air pressure range (typically measured in PSI and Bar). Maintaining the right air compressor pressure ensures that each cycle—whether it's a strike or a rotation—delivers the exact force required for a professional finish. - Extended Tool Life

Using the correct air pressure prevents internal components like O-rings and pistons from being overworked. By regulating your air compressor pressure, you avoid the mechanical strain that leads to premature failure and costly repairs. - Operational Safety

Fluctuating or extreme air pressure can lead to unpredictable tool behavior. Properly managed air compressor pressure reduces the risk of hose bursts or tool malfunctions, keeping the operator safe. - Energy Efficiency

When your air compressor pressure is set correctly, the motor doesn't have to cycle unnecessarily. This not only saves electricity but also reduces the overall wear and tear on your compressor unit.

【Learn More: All You Need to Know to Choose Your Perfect Air Nailers, Air Staple Guns, and Air Pliers】

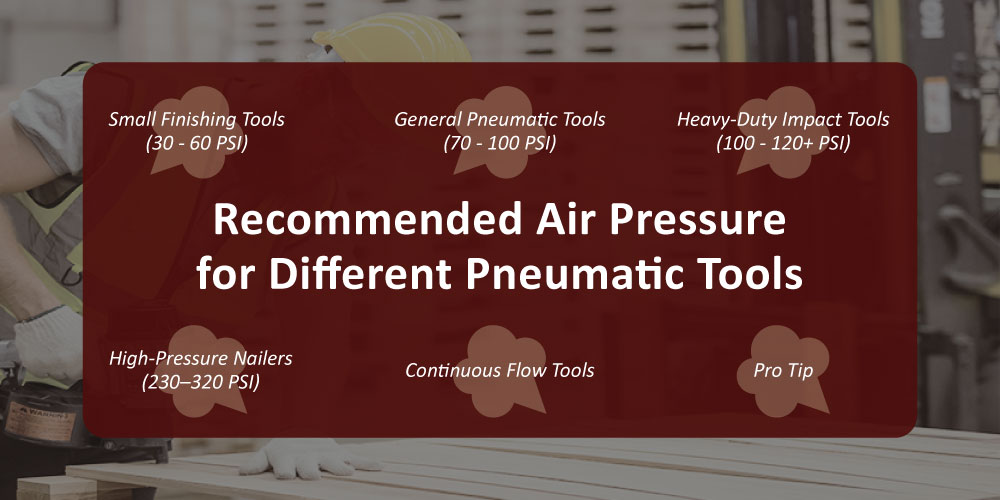

Recommended Air Pressure for Different Pneumatic Tools

To get the most out of your equipment, you must match your air compressor pressure to the specific requirements of the tool in your hand. Using a "one-size-fits-all" approach often leads to poor performance or accidental damage. While most handheld pneumatic tools are designed to operate around 90 PSI, the optimal air pressure can vary depending on the tool’s size and function.

Standard Pressure Guidelines

- Small Finishing Tools (30–60 PSI)

Lightweight tools such as airbrushes or small HVLP (High Volume Low Pressure) spray guns require lower, more controlled air pressure to ensure precision and a smooth finish without overspray. - General Pneumatic Tools (70–100 PSI)

This is the "sweet spot" for the majority of workshop tools. Equipment like nail guns, staplers, and orbital sanders perform best when your air compressor pressure is maintained within this stable range. - Heavy-Duty Impact Tools (100–120+ PSI)

High-torque tools, such as large 1-inch impact wrenches used for heavy machinery or truck tires, may require higher air pressure to break loose stubborn, rusted bolts. - High-Pressure Nailers (230–320 PSI)

In professional construction—such as fastening to concrete or steel—high-pressure nailers are used. These require a dedicated high-pressure air compressor pressure system, allowing the tool to be more compact and powerful than standard pneumatic versions. - Continuous Flow Tools

For tools that run constantly, like grinders or sanders, it is vital to monitor the CFM (Cubic Feet per Minute) alongside your air pressure to ensure the compressor can keep up with the demand. - Pro Tip

Always check the manufacturer's stamp on the tool body or the user manual. Setting your air compressor pressure exactly to the tool's rating—rather than the maximum tank pressure—will significantly extend the life of your gear.

【Learn More: Maximize Tool Performance: 4 Smart Ways to Pick the Best Air Tool Fittings】

Signs That Your Air Pressure is Insufficient

When your air compressor pressure fails to meet the tool's requirements, productivity grinds to a halt. Recognizing the early warning signs of low air pressure can prevent you from blaming the tool for what is actually a power supply issue.

Loss of Power and Torque

The most frequent symptom is a tool that feels "weak." If an impact wrench can’t break a bolt loose or a drill stalls easily, your air pressure is likely insufficient to drive the internal motor.

Protruding Fasteners

In carpentry, if nails or staples are consistently left standing above the surface, it means the air compressor pressure wasn't strong enough to drive the piston through the full stroke.

Inconsistent Speed (RPM)

You may notice your grinders or sanders "cycling"—speeding up and then slowing down. This happens when the air pressure drops as you use the tool and the compressor struggles to catch up.

Sluggish Trigger Response

A delay between the trigger pull and the tool's action is a classic sign of low air pressure buildup within the lines.

【Learn More: Nail Gun Leaking Air from Trigger? Step-by-Step Fix & Prevention】

The Risks of Over-Inflation

Many users mistakenly believe that "more air means more power," but exceeding the recommended air pressure is a recipe for disaster. Over-inflation creates excessive stress that your pneumatic system wasn't designed to handle.

Internal Component Failure

High air compressor pressure can blow out delicate O-rings, gaskets, and seals. Once these internal barriers fail, your tool will suffer from constant leaks and power loss.

Accelerated Wear and Tear

Running a tool at excessive air pressure forces it to operate at "redline" speeds. This causes bearings to overheat and mechanical parts to wear down months or even years earlier than expected.

Workpiece Damage

Too much power can be just as bad as too little. Over-pressurization can lead to "over-driving" nails through the wood or causing surface gouges with high-speed sanding discs.

Serious Safety Hazards

This is the greatest risk. Excessive air pressure can cause hoses to burst or, in extreme cases, cause the tool's housing or spinning accessories (like grinding stones) to shatter, leading to potential injury.

【Learn More: 5 Common Driver Unit Problems Every Air Nailer User Should Know】

Conclusion

Precision starts with the right tool. At VIM, we engineer our pneumatic nailers to handle the real-world conditions of a busy job site. While maintaining the perfect air compressor pressure is vital, our tools are designed with advanced internal valving to ensure consistent driving power, even when your air pressure fluctuates.

From the surgical precision of our pin nailers and finishing nailers to the rugged, high-capacity power of our coil nailers, VIM provides the professional-grade performance you need for any application. Whether you are doing delicate trim work or high-speed industrial assembly, our tools are built for accuracy, durability, and maximum longevity.

Get Started with VIM Today

Visit VIM's website or contact us directly to learn more about our offerings and how we can support your projects.

Article Classification

Recent Articles

- How Proper Air Pressure Safeguards Your Pneumatic Tools and Investment

- Pneumatic vs. Electric Nailer: How to Choose the Best Option for Your Workflow

- Avoid Costly Jams: 5 Proven Hog Ring Plier Repair Solutions that Work

- 4 Simple Ways to Maintain Your Hog Ring Plier for Better Performance

- Narrow vs Wide Crown Stapler: 3 Steps to Make the Right Choice