The Hidden Force in Every Staple: 9 Point Types That Make Fastening Last

In the world of fastening, a staple may look like a simple piece of metal, but its performance depends heavily on one small detail—the staple point. The shape of this tip decides how the staple penetrates the material, how securely it holds, and whether it causes splitting or fiber damage. From woodworking and furniture assembly to flooring, insulation, and upholstery, every trade relies on choosing the right point design to achieve strength and durability.

This discussion highlights the role of the staple point, outlines the ten most widely recognized designs—including the well-known divergent staple—and explains the strengths and applications of each. With this knowledge, professionals and craftsmen can make informed choices that directly improve fastening quality and overall results.

【Related product: Various Staples】

What Is a Staple Point?

A staple point refers to the specific shape of the tip at the end of each staple leg. While a staple may look simple, the design of its point has a major influence on how it penetrates material and how securely it holds once driven.

A staple point refers to the specific shape of the tip at the end of each staple leg. While a staple may look simple, the design of its point has a major influence on how it penetrates material and how securely it holds once driven.

In practical applications such as woodworking, upholstery, construction, and other forms of industrial fastening, the staple point determines whether the staple enters cleanly, resists pulling out, or avoids damaging the surface. For example, a sharp chisel staple point cuts quickly into wood fibers, while a divergent staple spreads its legs apart inside the material to maximize grip.

Different staple point designs offer trade-offs between penetration, holding strength, and material protection. Some minimize the risk of splitting thin wood, others reduce fiber damage in fabrics, and still others are optimized for maximum lateral grip. Choosing the correct staple point is therefore just as important as selecting the right staple size or gauge when aiming for a strong and durable connection.

【Extended reading: Make Every Connection Count: 4 Clear Strategies to Choose the Best Fastener Materials】

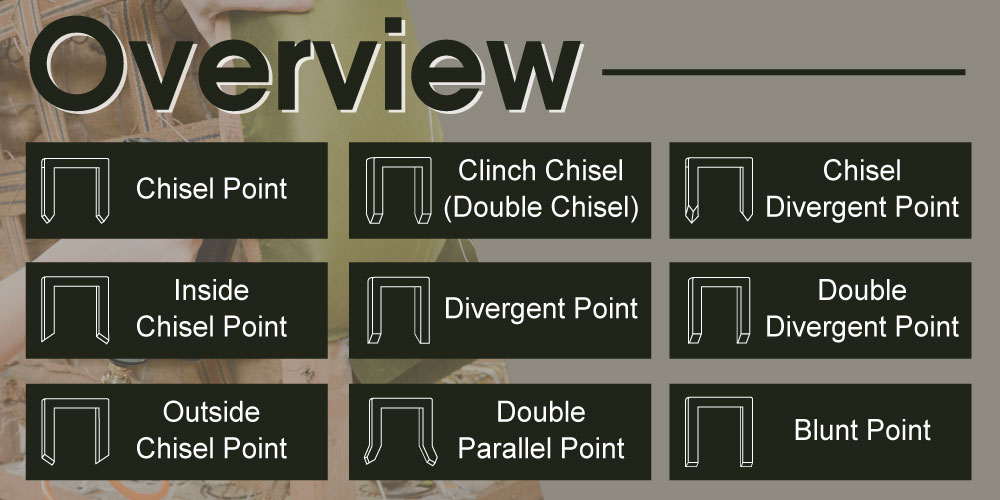

Overview of Staple Point Types

Across the fastening industry, there are around ten widely recognized staple point designs. Each point style is engineered to address different materials and fastening requirements, from clean penetration in hardwood to strong lateral grip in upholstery. Below is a quick overview of the most common types:

Across the fastening industry, there are around ten widely recognized staple point designs. Each point style is engineered to address different materials and fastening requirements, from clean penetration in hardwood to strong lateral grip in upholstery. Below is a quick overview of the most common types:

Chisel Point (C)

The standard staple point design, featuring an angled tip that allows for smooth penetration into wood and general-purpose use.

Inside Chisel Point (IC)

Both legs cut inward, helping to reduce splitting in softer woods while maintaining secure fastening.

Outside Chisel Point (OC)

The legs angle outward, providing better holding strength in wider grain or harder materials.

Clinch Chisel / Double Chisel (CC)

A twin-bevel cut where the legs tend to clinch sideways after entry, increasing grip and stability.

Divergent Point (DP)

One of the most widely used designs, also known as the divergent staple. Its legs spread outward inside the substrate, creating strong lateral resistance and excellent holding power.

Double Parallel Point (DPP)

Designed to penetrate nearly parallel, minimizing the risk of splitting thin panels, veneers, or delicate surfaces.

Chisel Divergent Point (CD)

A hybrid combining chisel penetration with divergent spreading action, balancing ease of entry and pull-out resistance.

Double Divergent Point (DD)

Both legs diverge strongly in opposite directions, delivering maximum grip in tough applications.

Blunt Point

Flat-ended staples that avoid fiber damage, making them ideal for fabrics, upholstery, and decorative finishes.

Together, these staple point types form the foundation of industrial fastening, allowing manufacturers, woodworkers, and upholsterers to choose the best point for strength, durability, and material protection.

【Extended reading: 14 Surface Treatments That Matter: A Closer Look at Fastener Finishing】

Detailed Guide: Strengths and Uses of Each Point Type

Chisel Point (C)

Chisel Point (C)

This is the most common staple point, designed for smooth penetration with its angled tip. It offers excellent versatility and is widely used in general woodworking, cabinet assembly, and light construction where a staple must enter cleanly without excessive resistance.

Inside Chisel Point (IC)

With both legs cut inward, this staple point reduces the risk of splitting softwoods such as pine or cedar. By keeping the staple legs directed toward each other, it creates a secure hold in furniture frames and other applications where the wood must remain structurally sound.

Outside Chisel Point (OC)

The legs of this staple point angle outward, delivering a stronger bite in dense or wide-grain materials. It is especially effective in hardwoods, particle board, and flooring, where extra grip strength is needed to prevent loosening over time.

Clinch Chisel / Double Chisel (CC)

This variation of the chisel design uses a twin-bevel cut that causes the staple legs to bend sideways after penetration. Such clinching action provides reinforced holding strength, making this staple point valuable in crating, and other heavy-duty industrial uses.

Divergent Point (DP)

Known commonly as the divergent staple, this design drives the legs apart once inside the substrate. The spreading action delivers strong lateral resistance, which is particularly effective in upholstery, flooring, and insulation where a standard staple might loosen.

Double Parallel Point (DPP)

Unlike divergent designs, this staple point drives both legs nearly parallel, reducing the risk of splitting thin panels or damaging veneer-covered surfaces. It is often chosen for plywood, laminated boards, and decorative finishes, where maintaining a clean appearance is critical.

Chisel Divergent Point (CD)

A hybrid design that combines the angled entry of a chisel point with the spreading effect of a divergent staple. This staple point balances penetration and pull-out resistance, making it suitable for furniture assembly and paneling work where both strength and precision are required.

Double Divergent Point (DD)

In this aggressive design, both legs diverge strongly in opposite directions. As one of the most secure forms of staple point, it provides maximum grip and lateral resistance, often used in subflooring, decking, and other structural assemblies exposed to heavier stress.

Blunt Point

Instead of sharp tips, the blunt staple point features flat ends that minimize fiber damage during entry. This makes it the preferred option for upholstery, textiles, insulation sheets, and other delicate applications where surface protection is important.

Table: Staple Point Types – Features and Uses

| Staple Point Type | Description & Strengths | Typical Uses |

|---|---|---|

| Chisel Point (C) | The most common staple point, with angled tips for smooth penetration and versatility. | .General woodworking .Cabinet assembly .Light construction where staples must enter cleanly |

| Inside Chisel Point (IC) | Legs cut inward to reduce splitting in softer woods, keeping the material structurally sound. | .Furniture frames .Pine or cedar panels .Softwood applications |

| Outside Chisel Point (OC) | Legs angle outward for stronger bite in dense or wide-grain materials. | .Hardwoods .Particle board .Flooring projects requiring extra grip |

| Clinch Chisel / Double Chisel (CC) | Twin-bevel cut causes legs to clinch sideways after penetration, reinforcing hold. | .Pallet manufacturing .Crating .Heavy-duty industrial fastening |

| Divergent Point (DP) | Also called the divergent staple, legs spread apart inside the material, creating strong lateral resistance. | .Upholstery .Flooring .Insulation where staples must stay secure |

| Double Parallel Point (DPP) | Drives both legs nearly parallel, reducing splitting and surface damage, especially on veneer-covered panels. | .Plywood .Laminated boards .Decorative finishes where appearance is critical |

| Chisel Divergent Point (CD) | Combines chisel entry with divergent spreading action, balancing penetration and grip. | .Furniture assembly .Paneling .Jobs requiring both strength and precision |

| Double Divergent Point (DD) | Legs diverge strongly in opposite directions for maximum grip and lateral resistance. | .Subflooring .Decking .Structural assemblies exposed to stress or vibration |

| Blunt Point | Flat-ended staple point minimizes fiber damage and prevents tearing. | .Upholstery .Textiles .Insulation sheets .Delicate surface work |

Why Staple Point Choice Matters

Selecting the right staple point is just as important as choosing the correct size or gauge of staple. Each point type is engineered to perform differently depending on the application. In woodworking and furniture production, a chisel point may be ideal for fast, clean penetration, while in flooring or insulation, a stronger grip is required to ensure long-term stability. Upholstery work demands even greater care—using the wrong point can cause tearing in fabrics, visible fiber damage, or weak fastening that loosens over time.

Selecting the right staple point is just as important as choosing the correct size or gauge of staple. Each point type is engineered to perform differently depending on the application. In woodworking and furniture production, a chisel point may be ideal for fast, clean penetration, while in flooring or insulation, a stronger grip is required to ensure long-term stability. Upholstery work demands even greater care—using the wrong point can cause tearing in fabrics, visible fiber damage, or weak fastening that loosens over time.

When the wrong staple point is used, problems such as surface splitting, reduced holding power, or unnecessary material damage can occur. By contrast, choosing the right design enhances durability, maintains material integrity, and improves the overall finish of the project.

Among the various options, the divergent staple deserves special mention. Because its legs spread apart once inside the substrate, it provides excellent lateral holding strength, making it especially valuable in upholstery and construction where strong, reliable fastening is essential.

【Extended reading: Not Sure Which Gauge to Use? These 4 Points Make It Easy】

Conclusion

The choice of staple point directly affects fastening performance, from penetration and holding strength to the prevention of fiber damage or splitting. Whether it is woodworking, furniture making, flooring, insulation, or upholstery, understanding the differences among chisel points, blunt tips, and the divergent staple ensures that each project is finished with durability and precision. Selecting the right staple point is therefore not just a technical detail—it is the key to achieving professional and reliable results.

At VIM, we understand that every customer has unique fastening requirements. That is why we not only provide a complete range of standard staples, but also manufacture staple points tailored to specific applications. Whether you need enhanced grip for hardwood, minimal surface damage for upholstery, or a custom variation beyond conventional types, our team can deliver solutions designed to match your materials and production goals. By combining a broad selection with the flexibility of customization, we make sure our customers always have the right staple for the job.

Feel free to contact us with your requirements—we are here to assist you!

Article Classification

Recent Articles

- 5 Essential Checklist for Choosing Appropriate Flooring Nails

- Every Corrugated Fastener You Want—All Here in One Comprehensive Guide

- The 4 Carton Staples Issues Ruining Your Packaging—Solved in Minutes

- 5 Reasons Why VIM Concrete T Nails Deliver Unmatched Grip and Durability

- The Hidden Force in Every Staple: 9 Point Types That Make Fastening Last