Every Corrugated Fastener You Want—All Here in One Comprehensive Guide

Corrugated nails play an essential role in modern woodworking, furniture manufacturing, and light-frame assembly. Their distinctive wave-shaped profile provides exceptional lateral holding power, making them ideal for reinforcing joints and stabilizing wooden structures with speed and consistency. While they may appear simple at first glance, corrugated fasteners are engineered in a wide range of sizes, crowns, and configurations—each suited for different tools and assembly requirements.

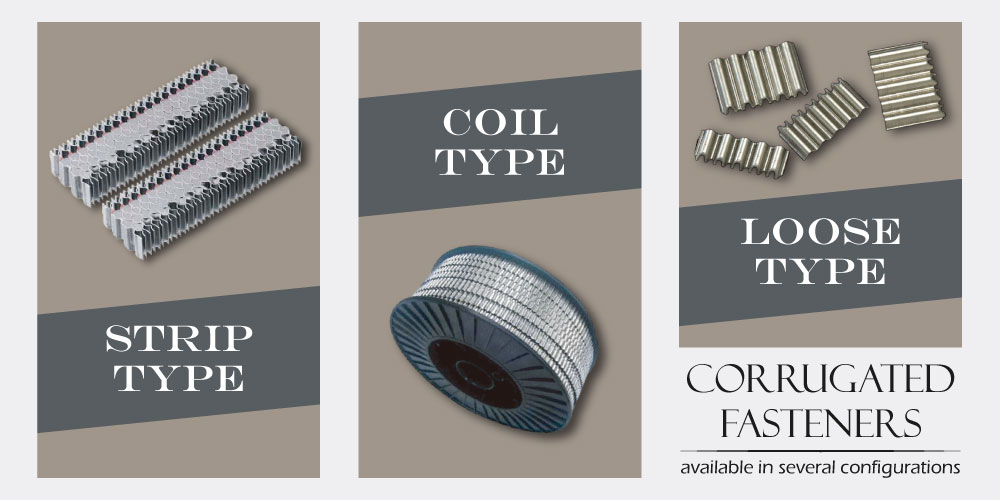

This article takes a closer look at how corrugated nails function, the various types available on the market, and the key differences between strip-type, coil-type, and loose-type fasteners. It also provides a detailed overview of popular series used across the industry and offers practical guidance on choosing the right corrugated nail size based on material characteristics, joint design, and tool compatibility. Whether you are involved in large-scale production or small-scale woodworking, understanding these factors will help you select the most reliable and efficient fastening solution for your application.

A Closer Look at Corrugated Nails

Corrugated nails—also known as corrugated fasteners—are thin, wave-shaped metal connectors designed to join two pieces of wood quickly and securely. Unlike traditional nails, they feature a corrugated (zig-zag) profile that increases surface grip and provides strong lateral holding power. This unique shape allows the fastener to bite into the wood fibers on both sides, creating a tight mechanical lock without the need for pre-drilling.

Corrugated nails—also known as corrugated fasteners—are thin, wave-shaped metal connectors designed to join two pieces of wood quickly and securely. Unlike traditional nails, they feature a corrugated (zig-zag) profile that increases surface grip and provides strong lateral holding power. This unique shape allows the fastener to bite into the wood fibers on both sides, creating a tight mechanical lock without the need for pre-drilling.

These fasteners are typically made from hardened steel and come in various crowns, lengths, and profiles to match different assembly requirements. Corrugated nails are commonly driven using pneumatic corrugated nailers, ensuring consistent penetration depth and precise alignment during high-volume production. They are widely used in wood frame joining, furniture manufacturing, cabinet assembly, casework, and other light-duty structural reinforcement tasks.

In woodworking and manufacturing, corrugated nails provide an efficient, cost-effective solution for reinforcing joints, preventing wood shifting, and improving overall structural stability. Their combination of speed, holding strength, and simplicity make them essential fasteners in many workshops and production environments.

【Related Products: Corrugated Fasteners】

How Corrugated Nails Work

Corrugated nails work by using their distinctive wave-shaped profile to create a strong mechanical lock between two pieces of wood. Unlike traditional smooth nails that rely mainly on downward penetration, corrugated fasteners are driven horizontally across a joint. As the corrugated profile enters the wood, each ridge and valley bites into the surrounding fibers, generating high lateral holding power and preventing the material from shifting under load.

Corrugated nails work by using their distinctive wave-shaped profile to create a strong mechanical lock between two pieces of wood. Unlike traditional smooth nails that rely mainly on downward penetration, corrugated fasteners are driven horizontally across a joint. As the corrugated profile enters the wood, each ridge and valley bites into the surrounding fibers, generating high lateral holding power and preventing the material from shifting under load.

When driven with a pneumatic corrugated nailer, the fastener is installed at a controlled depth and angle to ensure full engagement of the corrugated profile. The tool applies a sharp, even impact that forces the fastener across the joint, compressing the wood fibers and increasing surface contact. This action forms an interlocking connection that reinforces weak or open joints without the need for pre-drilling or complex clamping systems.

Because the fastener spans both pieces of wood, it effectively bridges gaps and stabilizes joints that may have loosened over time due to humidity changes, wear, or structural stress. The broad contact area created by the corrugated shape distributes force more evenly than conventional nails, making corrugated fasteners especially effective for furniture frames, casework, panel assembly, and general wood reinforcement.

【Extended reading: Corrugated Fastener Gun: 7 Reasons You Need This Tool】

Different Types of Corrugated Nails

Corrugated fasteners are available in several configurations to suit different woodworking, furniture, and light-frame assembly needs. They are typically categorized into normal strip type, coil type, and loose type, each designed for specific tools and fastening requirements. Below are an overview of each type and the popular series commonly used in the industry.

Corrugated fasteners are available in several configurations to suit different woodworking, furniture, and light-frame assembly needs. They are typically categorized into normal strip type, coil type, and loose type, each designed for specific tools and fastening requirements. Below are an overview of each type and the popular series commonly used in the industry.

Strip Type Corrugated Nails

Strip-type corrugated fasteners are the most common form, supplied in straight, collated strips for use with pneumatic corrugated nailers. They feature a flat, wave-shaped profile with consistent spacing, making them ideal for high-volume production, wood frame joining, casework, and general furniture assembly. Below are the major series available in the market:

X Series Corrugated Nails

With a 25 mm crown and lengths ranging from 6 to 15 mm, designed for use with tools such as the VIM CF254S and SENCO SC2.

WM Series Corrugated Nails

Featuring an 18.6 mm crown and lengths between 6 and 12 mm, making it suitable for VIM CF185S and BeA WM12-156 corrugated nailers.

W Series Corrugated Nails

Built with a 25 mm crown and lengths from 6 to 15 mm, providing compatibility with the VIM CF254S, BeA WM15-358, and BeA W15-760.

WN Series Jumbo Corrugated Nails

Designed for heavy-duty tasks, the WN Series provides a 35 mm crown and lengths from 12 to 25 mm, suitable for VIM WN3525, BeA W25, Haubold WN18XI, Haubold WN25XII, and Prebena WN25SNS.

CF Series Corrugated Nails

Offering a 25 mm crown and lengths from 8 to 15 mm and can be used with BeA BA-T358, SENCO SC2, Duo-Fast CF100A, and Haubold WM15.

MCF124 Series Mini Corrugated Nails

Compact in size, the MCF124 Series features a 12.4 mm crown and lengths ranging from 6 to 16 mm for fine-assembly applications.

MCF120 Series Micro Corrugated Nails

Engineered with a smaller 12 mm crown and lengths from 6 to 16 mm, the MCF120 Series is ideal for precision light-duty wood joining.

GCN20 Series Corrugated Nails

The GCN20 Series incorporates a 12.7 mm crown and lengths between 10 and 13 mm, compatible with Paslode MA-C20N fastening tools.

GC20 Series Corrugated Nails

Designed with a wider 26.4 mm crown and lengths from 10 to 13 mm, the GC20 Series suits VIM CF264P, Paslode MA-C20, and Paslode PCF1000.

Coil Type Corrugated Nails

Coil-type corrugated fasteners are rolled into compact coils, offering high capacity and reduced reloading frequency—ideal for continuous production lines, large-scale furniture manufacturing, and automated assembly systems. Their uniform corrugated profile ensures smooth feeding and consistent penetration throughout operation.

NR Series Corrugated Nails

Featuring a 12 mm crown (pitch) and is available in lengths ranging from 6 to 16 mm. Supplied in rolled coils for higher feeding capacity, they are well-suited for production environments that demand fewer reloads and stable fastening performance.

Loose Type

Loose-type corrugated fasteners are supplied as individual slices, making them suitable for manual application, repairs, custom assembly work, and tools designed for single-feed loading. They are often used in workshops or low-volume production settings where flexibility and ease of handling are essential.

ZB5 & WB5 Series Corrugated Nails

These series come with a 25 mm crown and lengths between 9 and 25 mm, offering a versatile loose type fastening option for general wood joining, reinforcement, and repair applications.

6WB Series Corrugated Nails

Built with a broader 31 mm crown and lengths from 9 to 25 mm, the 6WB Series provides enhanced holding capacity for heavy-duty applications requiring a wider corrugated profile.

Corrugated Fastener Overview Table

| Fastener Type | Series | Crown | Length | Suitable Tools |

|---|---|---|---|---|

| Strip | X | 25 mm | 6 to 15 mm | . VIM CF254S . SENCO SC2 |

| WM | 18.6 mm | 6 to 12 mm | . VIM CF185S . BeA WM12-156 |

|

| W | 25 mm | 6 to 15 mm | . VIM CF254S . BeA WM12-156 . BeA W15-760 |

|

| WN | 35 mm | 12 to 25 mm | . VIM WN3525 . BeA W25 . Haubold WN18XI . Haubold WN25XII . Prebena WN25SNS |

|

| CF | 25 mm | 8 to 15 mm | . BeA BA-T358 . SENCO SC2 . Duo-Fast CF100A . Haubold WM15 |

|

| MCF124 | 12.4 mm | 6 to 16 mm | . Fine-assembly corrugated nailers | |

| MCF120 | 12 mm | 6 to 16 mm | . Generic micro corrugated nailers | |

| GCN20 | 12.7 mm | 10 to 13 mm | . Paslode MA-C20N | |

| GC20 | 26.4 mm | 10 to 13 mm | . VIM CF264P . Paslode MA-C20 . Paslode PCF1000 |

|

| Coil / Roll | NR | 12 mm | 6 to 16 mm | . Coil-fed corrugated fastening equipment |

| Loose | ZB5 & WB5 | 25 mm | 9 to 25 mm | . Manual corrugated fastener applicators |

| 6WB | 31 mm | 9 to 25 mm | . Heavy-duty loose-type corrugated nailers |

Choosing the Right Corrugated Nail Size

Selecting the appropriate corrugated nail size is essential for achieving strong, stable joints and preventing wood damage during assembly. Corrugated fasteners vary in crown width, length, and profile, and each dimension influences how the fastener performs once driven into the material. The following considerations can help ensure proper fastener selection for different woodworking and manufacturing tasks.

Selecting the appropriate corrugated nail size is essential for achieving strong, stable joints and preventing wood damage during assembly. Corrugated fasteners vary in crown width, length, and profile, and each dimension influences how the fastener performs once driven into the material. The following considerations can help ensure proper fastener selection for different woodworking and manufacturing tasks.

Crown Width: Matching Holding Power to Joint Requirements

Crown width determines how much surface area the fastener covers across the joint. Wider crowns generally provide greater lateral holding strength, making them suitable for joints that may experience shifting or repeated stress. Narrower crowns are preferred for fine-assembly work, small components, or areas where the fastener should remain less visible. Selecting an appropriate crown width ensures the joint receives adequate reinforcement without overwhelming the material.

Fastener Length: Balancing Penetration and Material Thickness

Corrugated fastener length affects penetration depth and overall anchoring strength. Shorter lengths are ideal for thin stock or delicate components, where excessive penetration could cause splitting or surface damage. Longer lengths offer stronger reinforcement for thicker materials but must be chosen carefully to avoid driving through the workpiece. Assessing wood thickness and joint geometry helps determine the optimal fastener length for a stable connection.

Wood Type and Material Behavior

Different wood species respond differently to corrugated fasteners. Softwoods compress more easily, often requiring slightly longer or broader fasteners to achieve the desired holding force. Hardwoods resist compression and may need shorter or narrower options to avoid surface cracking or insertion difficulty. Considering wood density, grain direction, and surface condition helps ensure reliable fastener performance across various materials.

Tool Compatibility and Driving Method

The tool used—whether a pneumatic corrugated nailer, coil-fed system, or manual applicator—plays a critical role in nail size selection. Each tool supports a specific range of crown widths and lengths, and using fasteners outside that range may affect feeding reliability or driving depth. Ensuring proper tool compatibility allows each fastener to be driven consistently and securely, improving overall assembly efficiency.

Application Demands and Structural Expectations

The intended use of the finished product should guide fastener selection. Lightweight assemblies may only require a narrow crown and short penetration, while structural frames or reinforcement tasks benefit from larger, more robust fasteners. Evaluating load direction, stress points, and long-term durability requirements helps in selecting a corrugated nail size that matches real-world performance expectations.

Conclusion

Corrugated nails offer a dependable and efficient method for reinforcing wood joints, preventing material shifting, and improving the overall durability of assembled structures. By understanding how these fasteners work, recognizing the differences between various strip, coil, and loose-type configurations, and selecting the appropriate crown width and length for each task, woodworkers and manufacturers can significantly enhance fastening performance and production efficiency.

With a wide selection of corrugated fastener series available—each compatible with different tools and assembly conditions—choosing the right specification is essential for achieving consistent, high-quality results. Whether used in furniture frames, casework, cabinet structures, repair work, or automated production environments, corrugated nails remain a versatile and indispensable component in the woodworking and manufacturing industries.

If you need assistance selecting the right corrugated fasteners for your application or would like support from our technical team, please feel free to contact us.

Article Classification

Recent Articles

- 5 Essential Checklist for Choosing Appropriate Flooring Nails

- Every Corrugated Fastener You Want—All Here in One Comprehensive Guide

- The 4 Carton Staples Issues Ruining Your Packaging—Solved in Minutes

- 5 Reasons Why VIM Concrete T Nails Deliver Unmatched Grip and Durability

- The Hidden Force in Every Staple: 9 Point Types That Make Fastening Last