The 4 Carton Staples Issues Ruining Your Packaging—Solved in Minutes

In industrial packaging, how a carton is sealed often determines how well the product survives storage, handling, and long-distance transport. This is why carton staples remain a trusted fastening method across warehouses, fulfillment centers, and manufacturing environments. Unlike tape—which depends on adhesion—carton closing staples create a firm mechanical lock that stays secure through vibration, stacking pressure, and temperature changes.

This article walks through the essentials of carton staples: what they are, the main types available, the benefits they offer, how to choose the right specifications, and how to address common stapling issues. Whether your operation handles light cartons or heavy export-grade packaging, understanding these points will help you achieve stronger, more consistent carton sealing.

What Are Carton Staples?

Carton staples are specialized industrial fasteners used to securely close corrugated boxes, especially in heavy-duty or high-volume packaging environments. Unlike standard office staples, carton staples are designed with thicker wire, wider crowns, and longer legs—allowing them to penetrate multi-layer cardboard and create a firm mechanical lock. This makes them a preferred choice for packaging lines where strength, speed, and dependability matter more than aesthetics.

Carton staples are specialized industrial fasteners used to securely close corrugated boxes, especially in heavy-duty or high-volume packaging environments. Unlike standard office staples, carton staples are designed with thicker wire, wider crowns, and longer legs—allowing them to penetrate multi-layer cardboard and create a firm mechanical lock. This makes them a preferred choice for packaging lines where strength, speed, and dependability matter more than aesthetics.

You may also hear them referred to as carton closing staples, a name commonly used in warehousing, logistics, and manufacturing. Whether applied with a manual stapler or a pneumatic carton closing tool, the purpose is the same: to seal a carton tightly so it can survive long shipping routes, vibration, and rough handling.

Extended reading: Understanding Carton Stapler – 4 Points To Choose The Right Tool

Main Types of Carton Closing Staples

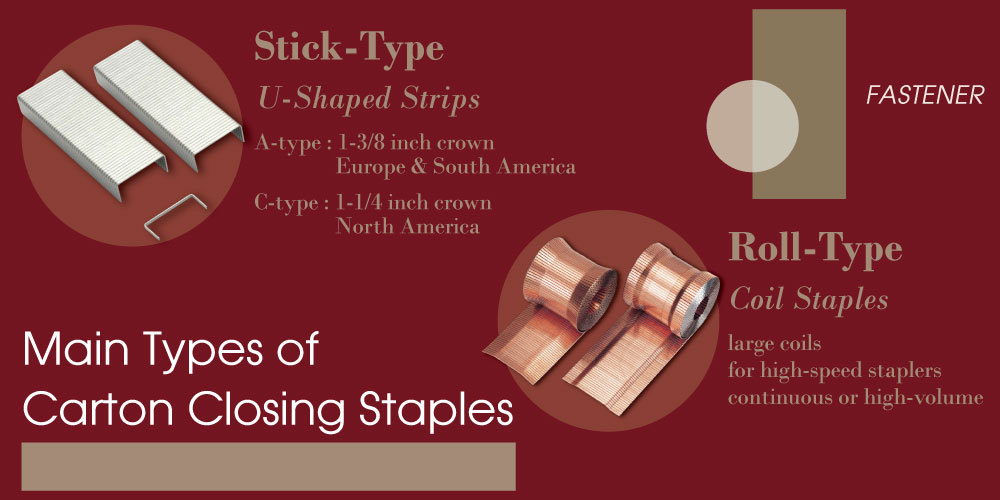

Carton closing staples are generally available in two major formats: stick-type staples and roll-type (coil) staples. Both are engineered for secure, industrial-grade carton sealing, but they serve different packaging environments and levels of production demand.

Carton closing staples are generally available in two major formats: stick-type staples and roll-type (coil) staples. Both are engineered for secure, industrial-grade carton sealing, but they serve different packaging environments and levels of production demand.

Stick-Type Carton Staples (U-Shaped Strips)

Stick-type carton staples are supplied in straight strips and used in both manual and pneumatic carton closing staplers. They are the most common choice in general warehousing, logistics centers, and medium-volume packaging lines.

Within this category, the two standard specifications are A-type and C-type, which differ mainly in crown width and regional preference. The A-type uses a 1-3/8 inch crown and is widely favored in Europe and South America, while the C-type features a 1-1/4 inch crown and remains the dominant standard in North America. Both deliver strong holding performance, and the choice typically depends on tool compatibility and local industry norms.

Pros

- Simple, widely compatible with common carton closing staplers

- Easy to load and replace

- Suitable for small to medium production volumes

- Lower equipment cost

Cons

- Requires more frequent reloads

- Less efficient for high-volume or automated lines

Related product: Carton Closing Staples

Roll-Type Carton Staples (Coil Staples)

Roll-type carton closing staples are wound into large coils and designed for high-speed pneumatic roll staplers. This format is built for efficiency and is widely used in continuous or high-volume packaging lines. The most common coil size contains 1,000 staples per roll, but many factories also use extra-large coils with 10,000 staples per roll to further minimize downtime and improve production flow.

Pros

- Extremely efficient for large-scale or nonstop packaging

- Fewer reloads thanks to 1,000-count and 10,000-count coil options

- Smoother, more consistent feeding—ideal for automated lines

- Reduces operator fatigue and improves overall throughput

Cons

- Requires specialized roll-type staplers

- Higher upfront tool investment

Related product: Rolled Carton Closing Staples

Benefits that Carton Staples Bring

Choosing carton staples for packaging delivers several advantages that go beyond simple box sealing. In modern logistics and industrial packaging, the ability to keep a carton securely closed throughout shipping, vibration, stacking, and handling is essential—and this is exactly where carton staples outperform many alternatives. Whether using stick-type or roll-type carton closing staples, the reliability they offer remains one of the key reasons they continue to dominate heavy-duty packaging environments.

Choosing carton staples for packaging delivers several advantages that go beyond simple box sealing. In modern logistics and industrial packaging, the ability to keep a carton securely closed throughout shipping, vibration, stacking, and handling is essential—and this is exactly where carton staples outperform many alternatives. Whether using stick-type or roll-type carton closing staples, the reliability they offer remains one of the key reasons they continue to dominate heavy-duty packaging environments.

Importance of Secure Carton Closing in Logistics and Industrial Packaging

A securely closed carton protects the product, prevents tampering, and ensures that boxes can withstand long routes through supply chains. Mechanical fastening from carton staples creates a firm lock that resists pull-out, impact, and environmental changes. This level of consistency is particularly important for warehouses, e-commerce fulfillment centers, food processing plants, and export packaging lines where failure is simply not an option.

Why Many Industries Prefer Carton Staples Over Tape

Although tape is quick and inexpensive, it struggles in conditions involving heavy loads, dusty surfaces, cold environments, or rough handling. Carton staples, on the other hand, penetrate the carton directly and create a physical interlock, making them far more dependable for demanding applications. They do not peel, warp, or lose adhesion—especially during temperature changes or extended storage. For this reason, industries managing high-value goods, dense materials, or export shipments still rely on carton closing staples as their go-to solution for secure, long-lasting carton sealing.

Extended reading: Handheld vs. Foot-Operated Carton Staplers: Which Is Better for Your Workflow?

How to Choose the Right Carton Closing Staples

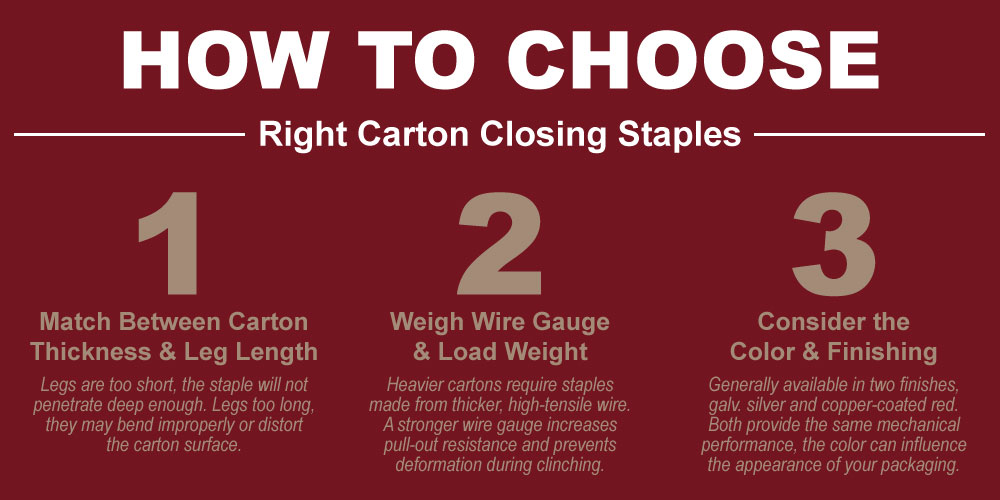

Selecting the right carton closing staples is essential for achieving secure, efficient, and reliable packaging. Different cartons, tools, and production environments all require different staple characteristics. By considering carton thickness, wire gauge, expected load weight, and the type of stapler being used, you can ensure that your sealing method performs consistently across your entire packaging line.

Selecting the right carton closing staples is essential for achieving secure, efficient, and reliable packaging. Different cartons, tools, and production environments all require different staple characteristics. By considering carton thickness, wire gauge, expected load weight, and the type of stapler being used, you can ensure that your sealing method performs consistently across your entire packaging line.

Match Between Carton Thickness and Leg Length

The leg length of carton staples must match the thickness of the corrugated board.

If the legs are too short, the staple will not penetrate deep enough to form a strong clinch.

If they are too long, the legs may bend improperly or distort the carton surface.

Choosing the right leg length ensures a proper mechanical lock and reduces the risk of box failure during transport.

Wire Gauge and Load Weight

Heavier cartons require staples made from thicker, high-tensile wire.

A stronger wire gauge increases pull-out resistance and prevents deformation during clinching.

Industries handling dense materials, liquids, electronics, or export shipments typically choose carton closing staples built from stronger wire to support higher load weight and reduce damage claims.

Extended reading: Not Sure Which Gauge to Use? These 4 Points Make It Easy

Consider the Color: Galvanized Silver vs. Copper-Coated Red

Carton staples are generally available in two finishes:

- Galvanized (silver)

- Copper-coated (reddish tone)

While both provide the same mechanical performance, the color can influence the overall appearance of your packaging. Silver staples work well with most standard cartons, but copper-coated staples blend especially nicely with natural kraft cartons, matching their warm brown tone for a more uniform look. Many users choose the finish based simply on visual preference or to keep their packaging appearance consistent with brand requirements.

Extended reading: 14 Surface Treatments That Matter: A Closer Look at Fastener Finishing

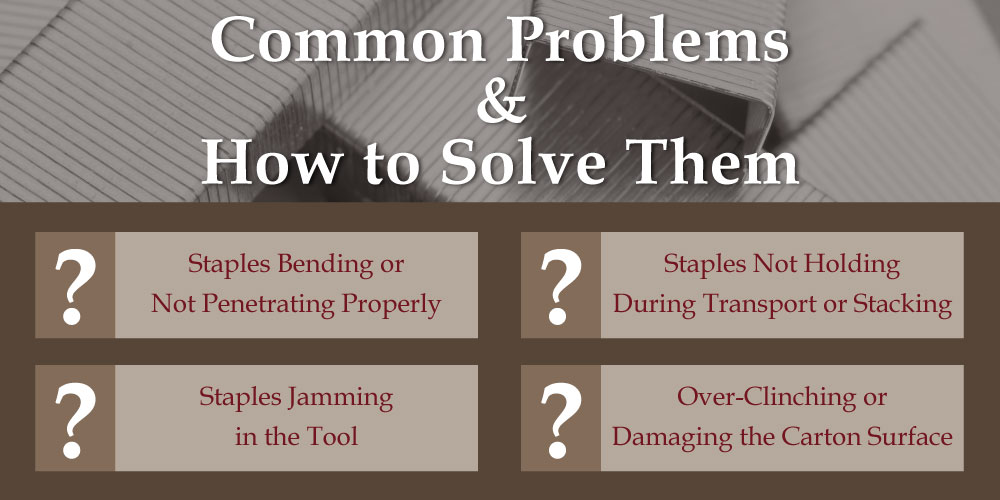

Common Problems & How to Solve Them

Even with high-quality carton closing staples, certain issues can occur during packaging—usually due to unmatched staple size, carton thickness, tool condition, or operator technique. Understanding these common problems and how to correct them helps ensure smooth, consistent sealing in any industrial stapling workflow.

Even with high-quality carton closing staples, certain issues can occur during packaging—usually due to unmatched staple size, carton thickness, tool condition, or operator technique. Understanding these common problems and how to correct them helps ensure smooth, consistent sealing in any industrial stapling workflow.

1. Staples Bending or Not Penetrating Properly

Possible causes:

- Legs too short for the carton thickness

- Dull driver blade in the stapler

- Insufficient air pressure on pneumatic tools

How to solve it:

- Choose a staple leg length that matches the corrugated board

- Inspect and replace worn driver blades when needed

- Ensure correct PSI settings for your pneumatic or air-powered stapler

2. Staples Jamming in the Tool

Possible causes:

- Using low-quality or inconsistent staples

- Incorrect staple size for the tool model

- Dirt, dust, or broken staples inside the magazine

How to solve it:

- Use high-quality carton closing staples that feed smoothly

- Always match staples to the correct stapler model

- Clean the tool regularly and remove any misaligned strips

3. Staples Not Holding During Transport or Stacking

Possible causes:

- Leg length too short

- Carton flaps not properly aligned before stapling

How to solve it:

- Move to longer staple legs for a stronger mechanical lock

- Ensure the top and bottom flaps are aligned and compressed before stapling

4. Over-Clinching or Damaging the Carton Surface

Possible causes:

- Excessive air pressure

- Clinch adjustment set too tight

- Using staples that are too long

How to solve it:

- Reduce air pressure to the manufacturer’s recommended PSI

- Fine-tune the clinch depth on the stapler

- Select a more suitable leg length to avoid crushing the carton

Extended reading: Stop Downtime: 4 Air Stapler Magazine Issues You Can Solve Today

Conclusion

Carton staples remain one of the most dependable sealing methods in modern industrial packaging thanks to their strength, consistency, and ability to maintain a secure mechanical lock during transport and handling. Selecting the proper crown width, leg length, wire gauge, and staple type helps ensure every carton is sealed firmly and performs reliably throughout the supply chain.

If you’re looking for carton closing staples that feed smoothly and clinch securely with both manual and pneumatic staplers, Vim supply a full range of A-type and C-type staples in galvanized (silver) and copper-coated (red) finishes. While the finish affects the appearance of your packaging, the precision of our wire quality and manufacturing process ensures stable performance in demanding environments.

Contact us anytime for samples or a quotation—our team is always ready to support your packaging operations.

Article Classification

Recent Articles

- 5 Essential Checklist for Choosing Appropriate Flooring Nails

- Every Corrugated Fastener You Want—All Here in One Comprehensive Guide

- The 4 Carton Staples Issues Ruining Your Packaging—Solved in Minutes

- 5 Reasons Why VIM Concrete T Nails Deliver Unmatched Grip and Durability

- The Hidden Force in Every Staple: 9 Point Types That Make Fastening Last