5 Reasons Why VIM Concrete T Nails Deliver Unmatched Grip and Durability

In the field of pneumatic fastening, precision and reliability depend on the quality of every single fastener. Among the many options available, T nails stand out for their distinctive “T”-shaped head, which provides both strong holding power and a smooth, flush finish.

This article introduces what T nails are and how they work, the different types available from VIM, and how they compare to T brads in terms of structure and application. You’ll also learn why VIM T nails, made with exclusive tooling and strict quality control in Taiwan, have become a trusted choice for professionals worldwide.

Overview & Applications of T Nails

T nails are a type of industrial fastener designed for use with pneumatic nailers, providing quick and reliable attachment between wood, light steel, or other construction materials. Their distinctive “T”-shaped head allows the nail to sit flush with the surface while offering exceptional holding power, making them ideal for projects that require both strength and a clean finish.

T nails are a type of industrial fastener designed for use with pneumatic nailers, providing quick and reliable attachment between wood, light steel, or other construction materials. Their distinctive “T”-shaped head allows the nail to sit flush with the surface while offering exceptional holding power, making them ideal for projects that require both strength and a clean finish.

In modern manufacturing and construction, T nails are widely used in furniture production, woodworking, interior finishing, light steel framing, and packaging assembly. They deliver stable and secure fastening performance even under high-stress conditions, ensuring long-term durability for both structural and decorative applications.

All T nails from VIM are precisely engineered to ensure smooth feeding, and consistent penetration, guaranteeing professional results every time.

【Read More: Concrete Nail Guns Uncovered: Find Out All the Answers You’re Looking For】

Types of T Nails

.jpg) At VIM, we manufacture a full range of T nails designed to meet diverse fastening requirements — from light woodworking to heavy-duty industrial applications. Each nail is produced with precise tolerances and strict quality control to ensure smooth feeding, consistent penetration, and full compatibility with VIM pneumatic T nailers.

At VIM, we manufacture a full range of T nails designed to meet diverse fastening requirements — from light woodworking to heavy-duty industrial applications. Each nail is produced with precise tolerances and strict quality control to ensure smooth feeding, consistent penetration, and full compatibility with VIM pneumatic T nailers.

T Nails

The standard version made from low-carbon steel (Ø2.2 mm), ideal for general woodworking, assembly, and interior finishing. They provide smooth driving and a clean, flush finish, perfect for soft materials such as wood, MDF, and plywood.

FST Nails

Crafted from high-carbon steel (Ø1.83 mm), these light yet strong T nails are available with chromate or black coating for excellent corrosion resistance. The smaller diameter allows faster shooting and cleaner penetration, making them ideal for mass production and applications requiring fine precision.

ST Nails

The heaviest-duty type of T nails, made from high-carbon steel (Ø2.2 mm) and featuring deep serrations along the shank. This design provides outstanding pull-out resistance and exceptional holding strength, making ST nails the best choice for dense wood, structural panels, and high-torque fastening conditions.

【Read More: Are You Confusing Pins and Brad Nails? Here's How to Tell Them Apart】

【Read More: Not Sure Which Gauge to Use? These 4 Points Make It Easy】

【Read More: Stop Guessing: 13 Proven Fastener Materials for Choosing the Right Nails and Staples】

【Read More: 14 Surface Treatments That Matter: A Closer Look at Fastener Finishing】

What’s the Difference Between T Nails and T Brads?

While T nails and T Brads share a similar “T”-shaped head design, they differ in size, strength, and application. The main distinction lies in their shank diameter and intended use.

While T nails and T Brads share a similar “T”-shaped head design, they differ in size, strength, and application. The main distinction lies in their shank diameter and intended use.

T Nails

Feature a broader head and thicker shank (Ø1.83 – 2.2 mm), giving them greater holding power and allowing them to penetrate harder materials such as dense wood, plywood, or even light steel plates. They are commonly used for structural joining, framing, and industrial assembly, where durability and strength matter most.

T Brads

By contrast, have a much thinner shank (Ø1.6 mm) and a narrower T-shaped head, leaving smaller marks on the surface. They are ideal for delicate woodworking, furniture finishing, and decorative trim, where a clean appearance is essential and heavy strength is not required.

Comparison Form

| Feature | T Nails | T Brads |

|---|---|---|

| Head Shape | Wide T-shaped head | Narrow, fine T-shaped head |

| Wire Diameter | Ø 1.83 – 2.2 mm | Ø 1.6 mm |

| Material Grip | High – for hardwood or light steel | Moderate – for softwood |

| Typical Use | . Structural joining . Framing . Industrial assembly |

. Furniture finishing . Trim . Decoration |

| Tool Type | Pneumatic T nailer | Pneumatic T brad nailer |

In summary, T nails deliver strength and holding power, while T Brads provide precision and a cleaner finish — making them complementary fasteners for different stages of construction or furniture production.

【Read More: What is Finishing Nailer? Differences Between Brad Nailer and Finish Nailer】

【Read More: All You Need to Know to Choose Your Perfect Air Nailers, Air Staple Guns, and Air Pliers】

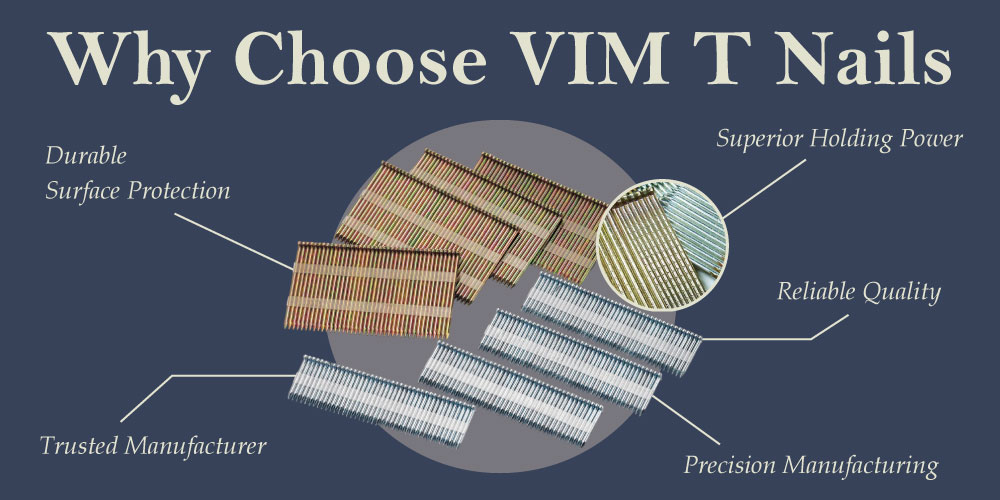

Why Choose VIM T Nails

When it comes to strength, consistency, and reliability, VIM T nails are trusted by professionals around the world. Every step—from material selection to tooling design—is controlled in-house to deliver unmatched fastening performance for woodworking and construction industries.

When it comes to strength, consistency, and reliability, VIM T nails are trusted by professionals around the world. Every step—from material selection to tooling design—is controlled in-house to deliver unmatched fastening performance for woodworking and construction industries.

1. Superior Holding Power

Deep serrations on ST nails provide exceptional grip and long-term stability, ensuring strong connections even in dense or high-stress materials. Each serration is produced using VIM’s exclusively developed dies and forming technology in Taiwan, allowing the grooves to be sharper, deeper, and more uniform than standard products — greatly enhancing pull-out resistance and overall fastening strength.

2. Reliable Quality

Every batch of T nails is test-fired before shipment, not only to check feeding and driving performance, but also to simulate real working conditions. This ensures consistent penetration, minimal jamming, and stable operation in pneumatic nailers.

3. Durable Surface Protection

FST nails feature chromate or black coating to protect against rust, oxidation, and surface wear. These finishes are ideal for long-term storage or use in humid or outdoor environments, maintaining a clean, professional look.

4. Precision Manufacturing

Every T nail is made under strict dimensional tolerances using high-accuracy forming equipment. This guarantees smooth feeding, accurate shooting, and consistent trajectory, improving tool efficiency and extending nailer lifespan.

5. Trusted Manufacturer

With proprietary tooling, independent R&D, and rigorous quality inspection, VIM stands as a dependable manufacturing partner. Our focus on stable quality and quick service has earned the trust of global distributors and professional users alike.

Conclusion

Built for precision and reliability, VIM T nails deliver the perfect balance of strength, clean finishing, and consistency for professionals in woodworking, furniture assembly, and light construction. From low-carbon T nails for general applications to high-carbon FST and ST nails for demanding jobs, each model is crafted with strict dimensional control and quality inspection to ensure stability, durability, and flawless performance.

Every batch of T nails is test-fired before shipment to guarantee smooth feeding, accurate penetration, and dependable driving in pneumatic tools. Enhanced with deep-serration technology and corrosion-resistant coatings, they provide superior grip and long-term reliability under real working conditions. Backed by VIM’s technical expertise and responsive global support, our T nails help professionals work faster and more confidently.

Contact us today to request samples or quotations and experience the strength and precision that define VIM T nails.

Article Classification

Recent Articles

- 5 Essential Checklist for Choosing Appropriate Flooring Nails

- Every Corrugated Fastener You Want—All Here in One Comprehensive Guide

- The 4 Carton Staples Issues Ruining Your Packaging—Solved in Minutes

- 5 Reasons Why VIM Concrete T Nails Deliver Unmatched Grip and Durability

- The Hidden Force in Every Staple: 9 Point Types That Make Fastening Last