5 Essential Checklist for Choosing Appropriate Flooring Nails

Installing a new hardwood floor is a significant investment that adds timeless beauty and value to your home. However, the secret to a floor that remains silent and sturdy for decades doesn't just lie in the quality of the wood—it’s in the fasteners you can't see. In the industry, these specialized fasteners are commonly referred to as flooring nails, but more accurately, they are known as cleat nails. While a novice might mistake them for regular nails, cleat nails are specifically engineered with a unique ribbed design to handle the natural expansion and contraction of wood.

Choosing the right cleat nails is the most critical step in any installation project. Using the wrong fastener can lead to frustrating squeaks, unsightly gaps, or even damaged planks as the seasons change. In this guide, we’ll dive deep into everything you need to know about these essential fasteners. From understanding the differences between T, L, and F cleats to choosing the perfect gauge and length for your specific wood species, we will help you ensure your flooring project is built to last.

What are Flooring Nails?

When discussing professional wood floor installation, the term flooring nails almost always refers to cleat nails. Unlike the common round-head nails you might use for general construction, these are specialized fasteners designed specifically for the tongue-and-groove system of hardwood flooring.

When discussing professional wood floor installation, the term flooring nails almost always refers to cleat nails. Unlike the common round-head nails you might use for general construction, these are specialized fasteners designed specifically for the tongue-and-groove system of hardwood flooring.

Cleat nails feature a unique, rectangular cross-section rather than a circular one. This shape is intentional; it allows the fastener to slice through the wood fibers instead of wedging them apart, which significantly reduces the risk of splitting the floorboards during installation. Another distinguishing feature of these flooring nails is the series of ribs or barbs along the shank. These ribs provide superior grip by locking into the subfloor and the wood planks, ensuring that the floor remains tight and stable over time.

Because they are driven into the wood at a 45-degree angle using a flooring nailer, cleat nails provide a hidden fastening solution. This ensures that the surface of your hardwood remains clean and smooth, while the robust design of the flooring nails handles the heavy foot traffic and structural demands of a residential or commercial building.

【Extended reading: 5 Reasons Why VIM Concrete T Nails Deliver Unmatched Grip and Durability】

Different Types of Flooring Nails

To achieve a professional finish, it is essential to understand the specific profiles of flooring nails available on the market. While they all function as specialized fasteners, the head design of cleat nails plays a significant role in how they interact with different wood species and installation tools.

To achieve a professional finish, it is essential to understand the specific profiles of flooring nails available on the market. While they all function as specialized fasteners, the head design of cleat nails plays a significant role in how they interact with different wood species and installation tools.

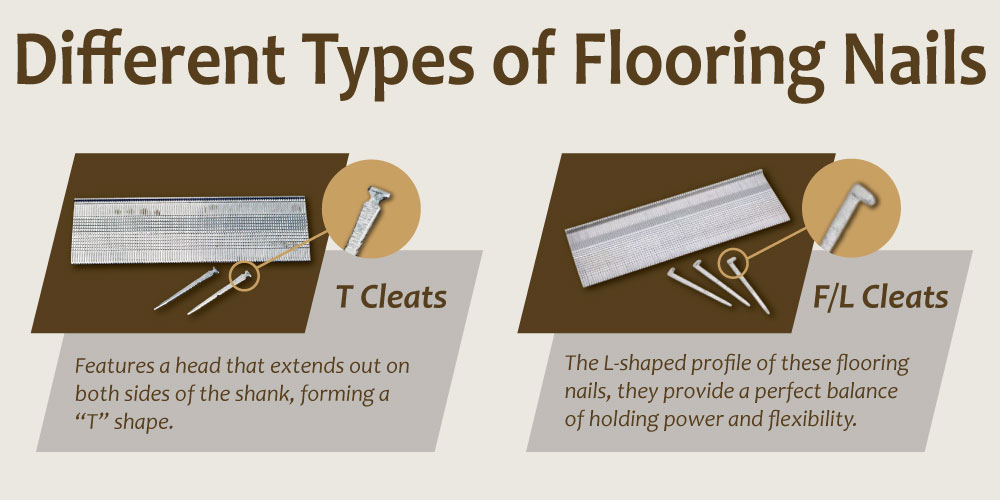

T Cleats

T cleats are a popular choice for many professional installers. These flooring nails feature a head that extends out on both sides of the shank, forming a “T” shape. This symmetrical design provides a very rigid hold and offers excellent downward pressure to secure the planks firmly against the subfloor. Because of their robust head structure, T-shaped cleat nails are often used with specific pneumatic nailer brands and are highly effective in ensuring a tight, gap-free fir for thicker hardwood planks.

F or L Cleats

The L-shaped profile of these flooring nails is slightly more forgiving than a T-cleat. When driven into the wood, the L-head is less likely to split the tongue of the board, which is a common concern when working with thinner materials or particularly brittle wood species. Many contractors prefer these cleat nails because they provide a perfect balance of holding power and flexibility, allowing the wood to settle naturally without compromising the integrity of the floor.

【Related products: T Cleats and F Cleats】

Why Use Cleat Nails for Hardwood Flooring

Professional installers consistently choose cleat nails over staples or traditional screws because they are engineered specifically for the physical demands of wood flooring. Here is why these flooring nails are the superior choice for your project.

Professional installers consistently choose cleat nails over staples or traditional screws because they are engineered specifically for the physical demands of wood flooring. Here is why these flooring nails are the superior choice for your project.

Allow for Wood Movement

Wood is natural material that expands and contracts with changes in humidity and temperature. One of the primary advantages of cleat nails is their ability to accommodate this movement. The unique ribbed shank of these flooring nails provides enough grip to hold the wood in place, while the metal’s slight flexibility allows the planks to shift minutely without snapping the fastener or cracking the wood. This ensures that your floor doesn’t buckle or gap excessively as the seasons change.

Strong Holding Power

The superior holding power of cleat nails is a result of both their design and the method of installation. These flooring nails are driven at normally 45-degree angle through the tongue of the board and deep into the subfloor. This angular penetration, combined with the serrated or barbed edges along the shank, creates a powerful mechanical lock.

Minimal Surface Damage

The slim, rectangular profile of cleat nails is designed to slice through wood fibers rather than forcing them apart. When driven at the correct angle through the tongue of the board, these flooring nails minimize the risk of splitting or "dimpling" the wood surface. By preserving the integrity of the tongue-and-groove joint, cleat nails ensure a flush fit between planks, resulting in a smooth and professional-looking finish.

Durability and Longevity

The durability of a wood floor is directly tied to the fatigue resistance of its fasteners. While many nails are made of steel, flooring nails are considered heavy-duty because of their specialized structural design. Unlike standard round nails that can snap under the constant lateral pressure of expanding wood, the rectangular shank of cleat nails is engineered to bend slightly without breaking. This allows the floor to endure the cumulative stress of decades of foot traffic and seasonal shifts. By maintaining a permanent, rigid grip through their serrated edges, these flooring nails ensure that the floor’s structural integrity remains intact, preventing the mechanical failure of joints that leads to costly long-term repairs.

How to Choose the Right Cleat Nails

Selecting the correct dimensions for your flooring nails is just as critical as the installation technique itself. Using cleat nails that are mismatched to your wood species or subfloor can lead to structural failure or surface damage. To find the ideal flooring nails for your project, you must consider the following five categories.

Selecting the correct dimensions for your flooring nails is just as critical as the installation technique itself. Using cleat nails that are mismatched to your wood species or subfloor can lead to structural failure or surface damage. To find the ideal flooring nails for your project, you must consider the following five categories.

Head Type

The head type of flooring nails determines how the fastener anchors the plank and which installation tool you will need. T-shaped cleat nails have a symmetrical head that provides excellent downward pressure, making them ideal for securing thick and heavy hardwood. On the other hand, F or L-shaped cleat nails feature a on sided head that acts like a hook. This profile is often preferred for thinner or more brittle wood because it is less likely to split the tongue of the board while still providing a firm and lasting hold.

Gauge

The gauge refers to the thickness of the shank of the cleat nails. Common sizes include:

- 16-Gauge

The industry standard for 3/4-inch solid hardwood, providing maximum strength for dense planks. - 18-Gauge

Designed for thinner engineered floors (1/2-inch or 3/8-inch) or very hard exotic species to prevent splitting. - 20-Gauge

These ultra-thin flooring nails are used for very thin wood flooring or delicate decorative strips where even an 18-gauge nail might cause damage.

【Extended reading: Not Sure Which Gauge to Use? These 4 Points Make It Easy】

Length

Choosing the length of your flooring nails based on the combined thickness of the hardwood and the subfloor. Common lengths include 1-1/2 inches, 1-3/4 inches, and 2 inches. The objective is to ensure that after the nail passes through the flooring, it penetrates the subfloor by at least 1/2 inch. For a standard 3/4-inch floor over a plywood base, 2-inch cleat nails are typically the standard. Using a flooring nail that is too short will result in a loose floor, while one that is too long may damage utilities hidden beneath the subfloor.

Material and Coating

The material of your flooring nails should match the environment and the wood species. Carbon steel is suitable for most projects, but stainless-steel cleat nails are essential for high-moisture areas or when working with woods high in tannic acid (like Oak) to prevent black staining. Furthermore, many high-quality cleat nails feature a heat-activated coating. This coating reduces friction as the nail is driven into the wood and then acts as an adhesive once seated, significantly enhancing the holding power of the flooring nails over time.

【Extended reading: Stop Guessing: 13 Proven Fastener Materials for Choosing the Right Nails and Staples】

Compatibility

Before purchasing cleat nails, you must verify their compatibility with your flooring tool. Flooring nails are typically glue-collated in strips to fit a specific angle. The magazine of flooring nailer is usually designed for one specific head type, and using the wrong head type can cause the tool to jam or break. Checking that cleat nails match the requirements of your flooring nailer will ensure a smooth workflow and prevent accidental damage to the hardwood during the installation process.

Conclusion

Achieving a flawless hardwood floor requires more than just high-quality planks and expert craftsmanship; it demands the right structural foundation. As we have explored, cleat nails are much more than simple fasteners. Their specialized rectangular design, ribbed shanks, and fatigue-resistant steel are what allow a floor to withstand the rigors of heavy foot traffic and the natural movement of wood over several decades.

Whether you are selecting between T-shaped or L-shaped heads, or determining the precise gauge and length for your specific wood species, the details matter. Choosing the correct flooring nails ensures that you avoid the common pitfalls of squeaky joints, split tongues, and loose planks. By matching your fasteners to your environment and installation tools, you are not just laying down wood—you are securing a long-term investment. With the right cleat nails, your hardwood floor will remain as silent, stable, and beautiful as the day it was installed.

If you are unsure which gauge or head type is best for your specific hardwood species, contact us today for expert advice and a competitive quote on our premium flooring nails.

Article Classification

Recent Articles

- 5 Essential Checklist for Choosing Appropriate Flooring Nails

- Every Corrugated Fastener You Want—All Here in One Comprehensive Guide

- The 4 Carton Staples Issues Ruining Your Packaging—Solved in Minutes

- 5 Reasons Why VIM Concrete T Nails Deliver Unmatched Grip and Durability

- The Hidden Force in Every Staple: 9 Point Types That Make Fastening Last