A Deep Dive into Coil Nails: 5 Reasons You Should Choose Coil Nails

Coil nails play a crucial role in construction and manufacturing, offering durability, high-speed nailing, and adaptability across a range of applications. In this guide, we’ll explore what makes coil nails indispensable, from their versatile design and production process to their key features and practical applications. You’ll also discover why VIM coil nails stand out for their quality, precision, and reliability, ensuring top performance in every project.

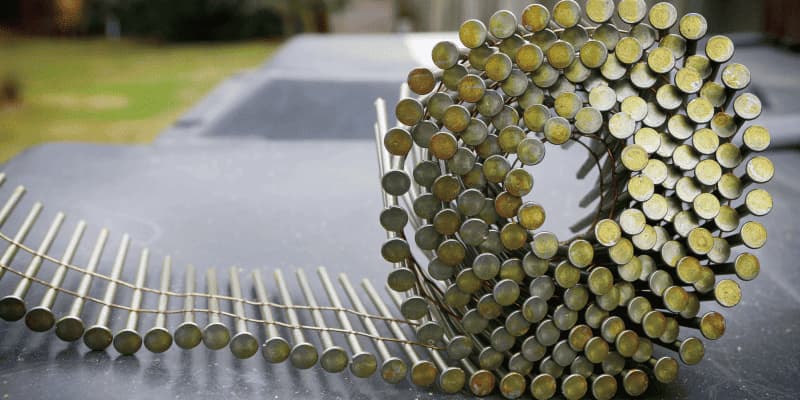

What Are Coil Nails?

Coil nails are versatile fasteners widely used in construction and manufacturing. Their unique design—arranged in a coil—enables high-speed, continuous nailing with minimal downtime, making them ideal for tasks where efficiency and precision are essential. Coil nails are especially popular for framing, roofing, siding, and pallet building due to their strong holding power and rust-resistant properties.

Coil nails are versatile fasteners widely used in construction and manufacturing. Their unique design—arranged in a coil—enables high-speed, continuous nailing with minimal downtime, making them ideal for tasks where efficiency and precision are essential. Coil nails are especially popular for framing, roofing, siding, and pallet building due to their strong holding power and rust-resistant properties.

Whether for indoor or outdoor use, coil nails offer durability and adaptability, handling various materials and load demands. With different shank, point, and head options available, they provide the flexibility needed to match specific project requirements and withstand challenging conditions.

Production Process of Coil Nails

The manufacturing process of coil nails involves several carefully controlled steps to ensure high quality, strength, and durability in each nail produced. Each stage is closely monitored to ensure that VIM coil nails meet rigorous standards, delivering reliability and performance across diverse construction and manufacturing projects.

The manufacturing process of coil nails involves several carefully controlled steps to ensure high quality, strength, and durability in each nail produced. Each stage is closely monitored to ensure that VIM coil nails meet rigorous standards, delivering reliability and performance across diverse construction and manufacturing projects.

1. Wire Rod Choosing

The process begins with selecting high quality wire rods as the raw material, setting a solid foundation for manufacturing strong and reliable nails.

2. Wire Drawing

The wire is drawn to the required thickness, ensuring it meets precise specifications for optimal strength and performance in each nail.

3. Nail Manufacturing

In this step, the wire is cut and shaped into individual nails, ensuring uniformity in length, diameter, and design, resulting in consistently high-quality nails.

4. Surface Treatment

To protect against corrosion, coil nails may receive various surface treatments such as galvanizing or electroplating, depending on their intended use. This added layer of protection ensures longer-lasting performance, especially in outdoor or high-moisture environments.

5. Heat Treatment

Certain coil nails undergo heat treatment to enhance hardness and toughness, particularly for high-strength applications that demand durability.

6. Color Coating

Based on customer requirements, a colored adhesive coating is applied to the coil nail surface. This coating not only allows for easy identification but also enhances stability when driven into materials.

7. Coil Collation

Individual nails are collated into coils for efficient use with coil nailers, minimizing reloading times and increasing productivity on job sites.

8. Quality Inspection

Before final assembly, each nail undergoes rigorous quality checks to confirm that its length, diameter, and surface treatment meet high standards. This step helps to reduce defects and maintain consistency in every batch.

9. Coil Collation Inspection

Once assembled into coils, each coil is inspected to ensure that nails are evenly spaced and securely held. This step prevents misfiring or jamming during application, improving efficiency and reliability.

10. Packaging and Labeling

The finished products are carefully packaged and labeled to protect them during transportation and storage, while also providing clear product specifications for easy identification by customers.

Key Features of Coil Nails

Coil nails are designed to provide high efficiency and versatility across various professional applications. Here are some unique features of coil nails that make them a preferred choice for secure and durable fastening.

Coil nails are designed to provide high efficiency and versatility across various professional applications. Here are some unique features of coil nails that make them a preferred choice for secure and durable fastening.

1. Efficient Collation Style

Coil nails are bound together in a spiral arrangement with metal wire or plastic, allowing for higher capacity in each loading cycle, ideal for continuous operations and reducing reload frequency.

2. High-Capacity Design

The coiled arrangement enables a greater number of nails per load compared to strip nails, making coil nails well-suited for high-volume applications and enhancing overall productivity.

3. Corrosion Resistance

Coil nails are often coated or galvanized for added rust and corrosion resistance, making them a reliable choice for outdoor projects and challenging environments.

4. Enhanced Holding Power

Coil nails are available with different shank types, including smooth, ring, and screw shanks. Ring and screw shanks provide added grip and reduce the risk of nails loosening over time.

5. Long-Lasting Durability

Quality coil nails are built to withstand vibrations and harsh conditions, offering reliable and long-lasting fastening solutions in demanding applications.

Applications of Coil Nails

Coil nails are an essential component in many construction and manufacturing projects due to their efficiency, strength, and versatility. Their high-capacity design and strong holding power make them ideal for a wide range of tasks, from roofing and framing to pallet assembly and deck building. Whether used for heavy-duty industrial purposes or more detailed woodworking, coil nails provide reliable performance that meets the demands of various applications. Below, we explore some of the most common and impactful uses of coil nails in different industries and projects.

Coil nails are an essential component in many construction and manufacturing projects due to their efficiency, strength, and versatility. Their high-capacity design and strong holding power make them ideal for a wide range of tasks, from roofing and framing to pallet assembly and deck building. Whether used for heavy-duty industrial purposes or more detailed woodworking, coil nails provide reliable performance that meets the demands of various applications. Below, we explore some of the most common and impactful uses of coil nails in different industries and projects.

Roofing

Coil nails are commonly used for attaching roofing shingles and other roofing materials, thanks to their high capacity and corrosion-resistant properties.

Framing and Sheathing

Ideal for framing walls and installing exterior sheathing, coil nails provide a secure and durable hold that can withstand structural stress.

Siding Installation

Coil nails are used to fasten wood, vinyl, or fiber-cement siding to the exterior of buildings, ensuring a firm and weather-resistant attachment.

Fencing

Perfect for building wooden fences, coil nails offer strong holding power, making them a reliable option for outdoor applications.

Pallet and Crate Manufacturing

Coil nails are frequently used in the mass production of wooden pallets and crates due to their ability to be loaded in high-capacity nail guns, speeding up the assembly process.

Deck Building

Used for fastening deck boards to the frame, coil nails ensure that the structure remains sturdy and secure over time.

Subflooring

Coil nails are often used to attach subfloor panels to joists, providing a stable base for flooring materials.

Furniture Manufacturing

For heavy-duty furniture that requires a strong and durable assembly, coil nails help keep wooden components securely attached.

Woodworking and Carpentry

Smaller coil nails are suitable for various woodworking projects, providing precise and consistent nailing.

Shipping and Packaging

Used to construct wooden shipping containers and boxes, coil nails provide the strength needed for secure and long-lasting packaging.

VIM Quality in Every Coil Nail

VIM’s coil nails stand out for their superior durability, precision engineering, and consistent performance across various construction and manufacturing applications. Designed with high-capacity collation and corrosion-resistant coatings, our coil nails are ideal for professional projects requiring strong holding power and long-lasting results. Each nail undergoes a rigorous production process to ensure quality, from wire selection to final inspection, providing users with dependable fastening solutions that reduce downtime and enhance productivity on the job. Whether you're working on roofing, framing, or detailed woodworking, VIM’s coil nails are crafted to deliver efficiency, reliability, and top-tier results in every application.

Conclusion

Coil nails are indispensable in construction and manufacturing due to their unique coiled design, high-speed nailing capacity, and versatility across diverse applications. From roofing and framing to detailed woodworking and furniture assembly, coil nails deliver consistent, durable fastening solutions that stand up to demanding environments. The production process—from wire selection to heat and surface treatments—ensures that each nail is built for strength and longevity, making them a reliable choice for projects requiring both durability and precision.

VIM’s coil nails further exemplify these qualities through rigorous quality checks and precision engineering, offering professionals a dependable solution that enhances productivity and reduces downtime. By choosing high-quality coil nails tailored to specific project needs, professionals can achieve efficient, long-lasting results, making coil nails a crucial tool in any serious builder’s toolkit. Whether your project demands high-capacity nailing for heavy-duty tasks or corrosion-resistant fasteners for outdoor use, coil nails provide the versatility and performance to meet these varied demands effectively.

Feel free to contact us with your requirements—we are here to assist you!

Article Classification

Recent Articles

- 5 Essential Checklist for Choosing Appropriate Flooring Nails

- Every Corrugated Fastener You Want—All Here in One Comprehensive Guide

- The 4 Carton Staples Issues Ruining Your Packaging—Solved in Minutes

- 5 Reasons Why VIM Concrete T Nails Deliver Unmatched Grip and Durability

- The Hidden Force in Every Staple: 9 Point Types That Make Fastening Last