Are You Confusing Pins and Brad Nails? Here's How to Tell Them Apart

In the world of fine woodworking, trim installation, and precision joinery, selecting the right fastener is critical to both the performance and appearance of a project. Among the most specialized options, Pin Nails—particularly in 23-gauge and 21-gauge—are trusted for creating nearly invisible joints without compromising material integrity. Whether you're using a pneumatic or electric Pin Nailer, these ultra-thin pins provide excellent control and a seamless finish.

In this article, we’ll explore what makes pin nails unique, how they differ from other nails like brad nails, and the key specifications that define their performance. By the end, you’ll understand how to choose the right pin nails and pin nailer setup to achieve professional results in your fastening applications.

What are Pin Nails?

Pin nails are slender, lightweight fasteners commonly used for precision woodwork where a clean, nearly invisible finish is essential. Typically available in 23-gauge and 21-gauge, these pins are significantly thinner than brads or finish nails, making them ideal for detailed applications.

Pin nails are slender, lightweight fasteners commonly used for precision woodwork where a clean, nearly invisible finish is essential. Typically available in 23-gauge and 21-gauge, these pins are significantly thinner than brads or finish nails, making them ideal for detailed applications.

Pin nails are offered in two main styles: Headless Pins, which leave no visible mark on the surface, and Micro Head Pins, which provide slightly better holding strength while maintaining a minimal footprint. Both types are designed for use cases where surface aesthetics and material integrity are critical.

Due to their minimal diameter and small or nonexistent head, pin nails can be driven into wood with virtually no surface disruption. This allows for tight, seamless joints without the need for filling or sanding. Although these pins have limited holding power on their own, they are often used in combination with wood glue to align parts during drying-delivering both accuracy and efficiency in assembly.

To drive these delicate fasteners, a pin nailer—a pneumatic or electric tool specifically designed for 23-gauge or 21-gauge pin nails—is used. This tool enables clean, controlled fastening without splitting the material, even in fragile or thin wood pieces.

【Extended reading: Air Pinner Buying Guide - 6 Points to Distinguish Air Pinner and Finishing Nailer】

Are Pin Nails the Same as Brad Nails?

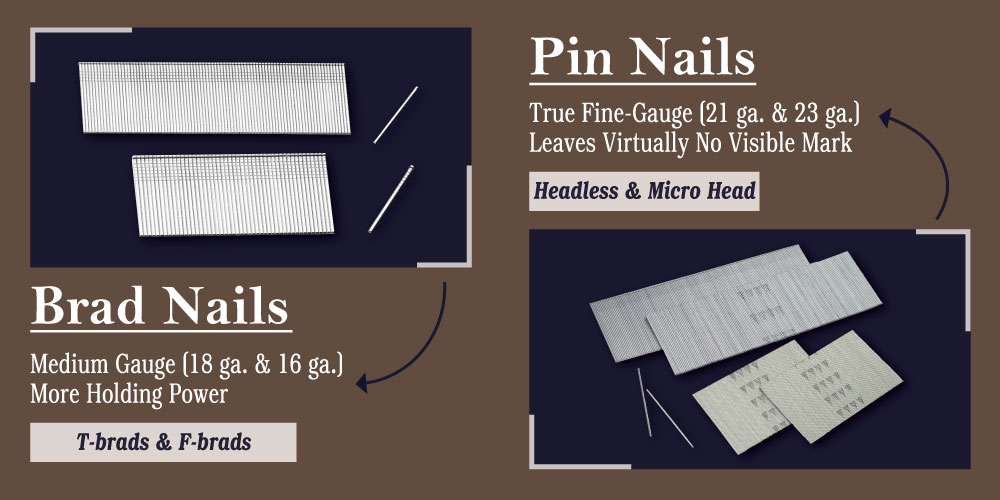

Although both Pin Nails and Brad Nails are used in delicate woodworking and trim applications, they are fundamentally different in terms of gauge, head design, holding strength, and intended usage. Selecting the right fastener starts with understanding these technical distinctions.

Although both Pin Nails and Brad Nails are used in delicate woodworking and trim applications, they are fundamentally different in terms of gauge, head design, holding strength, and intended usage. Selecting the right fastener starts with understanding these technical distinctions.

At VIM International, we supply both Brad Nails—including our T-brads and F-brads—and ultra-fine Pin Nails in 21 gauge and 23 gauge, available in headless and micro head variations. Each type of nail is designed to meet specific performance demands in furniture making, architectural millwork, and interior finishing.

Pin Nails: The True Fine-Gauge Fastener

Pin nails, especially those in 21-gauge and 23-gauge, are considered true fine-gauge fasteners are designed for precision woodwork. They are available in headless and micro head variants-the former leaves virtually no visible mark, while the latter offers slightly more holding strength with minimal surface impact.

Due to their minimal diameter and lack of a pronounced head, pin nails are primarily used in conjunction with adhesives. They serve to hold delicate material like veneers, small trims, or decorative moldings in place without splitting the wood. A specialized pin nailer is required to drive these ultra-thin pins cleanly and precisely.

Brad Nails: Medium Gauge, More Holding Power

By contrast, brad nails are generally offered in 18 gauge and 16 gauge, placing them in the medium gauge category. While they are frequently used in finishing tasks, their thicker profile and small head provide greater holding power than pin nails.

Brad nails are available in straight 0 degree or angled collations, typically 16 degrees or 20 degrees, depending on tool compatibility. This angled configuration enhances tool maneuverability, making it easier to access tight corners or vertical surfaces during trim installation.

Though brad nails leave a slightly more visible mark than pins, they strike a practical balance between aesthetics and strength. They are not compatible with pin nailers, and instead require brad nailer engineered for higher driving force and angled magazine configurations.

Comparison Chart: Pin Nails vs. Brad Nails

| Feature | Pin Nails | Brad Nails |

|---|---|---|

| Gauge | 21 Ga. or 23 Ga. | 16 Ga. or 18 Ga. |

| Head Type | . Headless . Micro head |

Small, Visible head |

| Collation Angles | Typically straight (0 degree) |

Straight or Angled (0, 16, or 20 degrees) |

| Surface Finish | Nearly invisible | Slightly visible |

| Holding Power | Lower | Higher |

| Splitting Risk | Very low | Low |

| Applications | . Veneer . Small trims . Decorative molding . Light frames |

. Baseboards . Door/window casings . Light paneling |

Pin Nail Selection Guide

As a precision-grad fastener, pin nails are widely used in fine woodworking, trim installation, and architectural millwork. Choosing the right type of pin depends on several key specifications, including head design, wire gauge, length material, and finish color. Each variation impacts how the nail performs during installation and how it interacts with different substrates when driven by a pin nailer.

As a precision-grad fastener, pin nails are widely used in fine woodworking, trim installation, and architectural millwork. Choosing the right type of pin depends on several key specifications, including head design, wire gauge, length material, and finish color. Each variation impacts how the nail performs during installation and how it interacts with different substrates when driven by a pin nailer.

Head Type

Pin nails are available in two primary head configurations, both types are compatible with pin nailers, but selecting the appropriate head type depends on whether the project prioritizes surface invisibility or structural grip.

- Headless Pins

Headless type leaves virtually no visible trace on the work surface, making them ideal for high-end finish applications where aesthetics are critical. - Micro Head Pins

It features a slightly raised head, offering improved holding strength without compromising the clean finish expected in fine joinery.

Gauge and Wire Size

Pin nails are classified as fine-gauge fasteners, typically manufactured in 23-gauge and 21-gauge sizes. Choosing the right gauge ensures that the pin nail seats correctly and cleanly without damaging fragile surfaces. The selected gauge must also match the specifications of the pin nailer being used.

- 23 Gauge

23-gauge pins are extremely thin, with a typical wire diameter of approximately 0.64 mm. They are ideal for ultra-delicate materials such as veneers, crown moldings, and narrow decorative trims. - 23 Gauge

21-gauge pins have a slightly larger wire diameter of around 0.84 mm, offering improved rigidity and holding strength while still maintaining a low risk of wood splitting. They are often used in applications where slightly more structural support is needed without compromising surface finish.

Length

Pin Nails are available in a wide range of lengths—from as short as 5 mm up to 50 mm—to accommodate various fastening depths and material thicknesses. Choosing the suitable pin length is essential for preventing blowout or under-penetration. Always confirm that the selected size is compatible with the magazine and driving capacity of your pin nailer.

- Ultra Short Pins (5 to 6 mm)

They are ideal for extremely thin materials, such as small decorative trims, veneer strips, or lightweight assembly tasks where minimal penetration is required.

【Related product: P606FL, PT606FL】 - Shorter Pins (10 to 20 mm)

It is commonly used for light trims or for temporarily holding components in place while adhesives cure. - Longer Pins (30 to 50 mm)

The longer pins are better suited for deeper penetrations in thicker wood pieces, providing greater alignment stability for cabinetry or millwork.

【Related product: 21 & 23 Gauge Pin Nailer】

Material and Finishing

The choice of material and surface finishing plays a critical role in the performance of pin nails, influencing durability, corrosion resistance, adhesive bonding, and visual appearance. These factors are especially important when working with different wood species, environmental conditions, or finishing standards.

- Galvanized Steel

Made from carbon steel with a zinc coating, galvanized pins offer reliable corrosion resistance and are suitable for most indoor and general-purpose applications. - Stainless Steel

Known for its high resistance to rust and chemical exposure, stainless steel is preferred for exterior use, high-humidity environments, or when maximum durability is required. - Copper or Brass-coated

These pins are often selected for decorative applications or specialized joinery, where color tone and oxidation properties are desirable for matching visible surfaces.

【Extended reading: Stop Guessing: 13 Proven Fastener Materials for Choosing the Right Nails and Staples】

Color

To further improve the visual finish, pin nails are available in several color coatings. The color selection ensures that the pin remains discreet and blends seamlessly into the finished surface, reducing the need for putty or paint touch-ups.

Conclusion

Choosing the proper pin nails and matching them with a reliable pin nailer can significantly impact the quality and longevity of your woodworking projects. Whether you're working with delicate veneers, intricate moldings, or light trim, using the right combination of fastener and tool ensures minimal surface disruption and maximum precision.

As a dedicated supplier of industrial-grade pins and pneumatic tools, VIM International is committed to helping professional users achieve flawless results. Our comprehensive portfolio of 21-gauge and 23-gauge pin nailers and pins, available in headless and micro head types, is engineered for accuracy, durability, and seamless finish. Partner with us to elevate your fastening performance—one pin at a time.

Article Classification

Recent Articles

- 5 Essential Checklist for Choosing Appropriate Flooring Nails

- Every Corrugated Fastener You Want—All Here in One Comprehensive Guide

- The 4 Carton Staples Issues Ruining Your Packaging—Solved in Minutes

- 5 Reasons Why VIM Concrete T Nails Deliver Unmatched Grip and Durability

- The Hidden Force in Every Staple: 9 Point Types That Make Fastening Last