Why Hog Rings are the Best Fastening Solution and How to Select

Hog rings are indispensable fasteners in industries like agriculture, automotive, upholstery, and construction. With their unique shape, including C-rings, D-rings, and Omega rings, these versatile rings provide secure and durable connections for various applications. Whether you are fastening fencing, repairing upholstery, or tackling industrial projects, hog rings are a trusted solution. This article will explore what hog rings are, their applications, how to choose the right type, common sizes of hog ring, and how to use and remove them effectively.

What are Hog Rings?

Hog rings have different types, such as C-rings, D-rings, and Omega rings. These durable metal rings are commonly used in various industries, including agriculture, automotive, upholstery, and fencing. Hog rings are typically applied using specialized pliers or pneumatic tools, allowing for quick and efficient fastening.

Hog rings have different types, such as C-rings, D-rings, and Omega rings. These durable metal rings are commonly used in various industries, including agriculture, automotive, upholstery, and fencing. Hog rings are typically applied using specialized pliers or pneumatic tools, allowing for quick and efficient fastening.

Their strong grip and resistance to wear make hog rings an excellent choice for tasks requiring long-lasting and robust connections. With varying sizes, materials, and coatings available, hog rings can be tailored to meet specific project needs, offering both strength and versatility.

【Extended Reading: Mastering Hog Ring Pliers: 9 Reasons You Need This Essential Tool 】

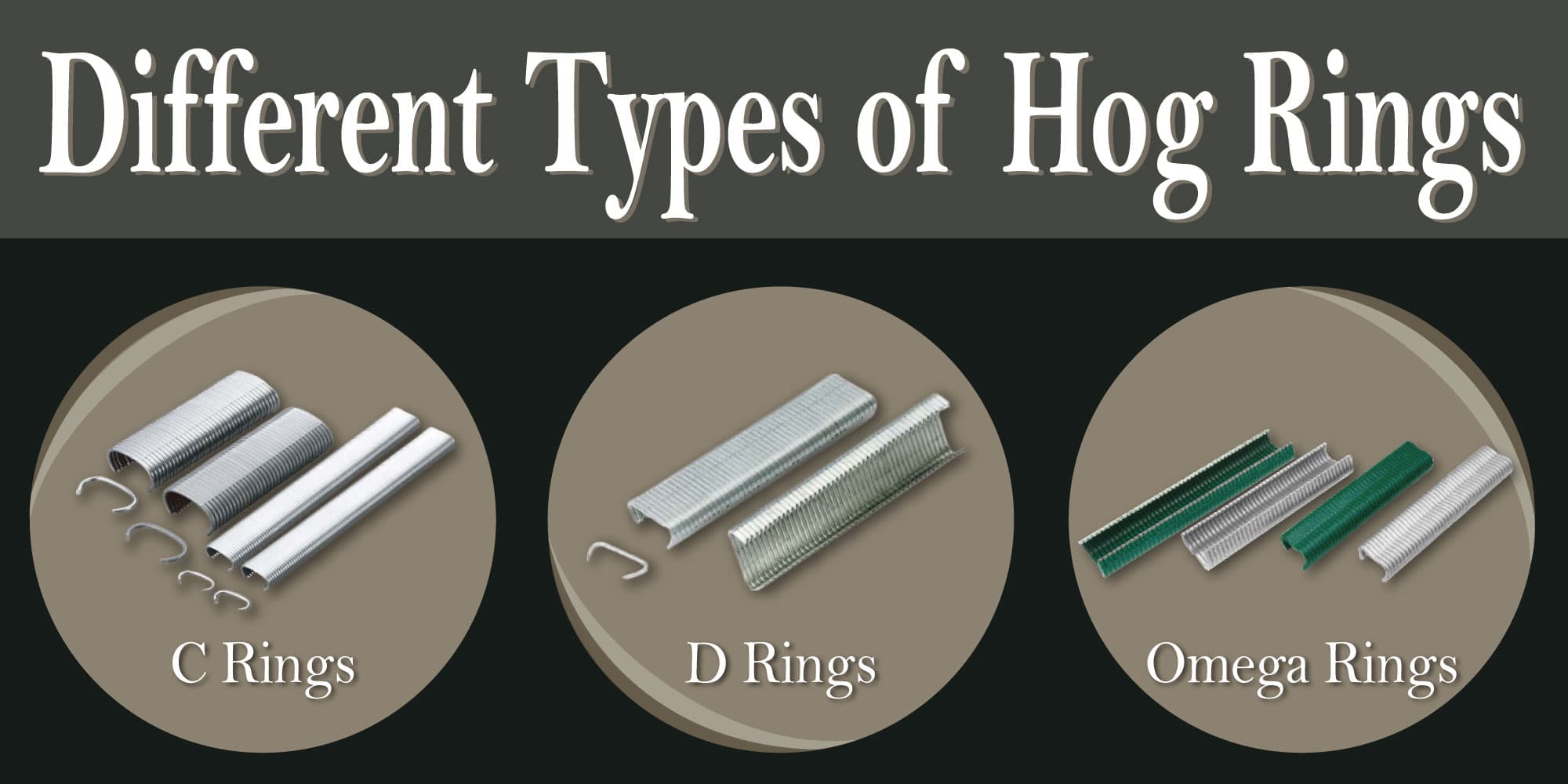

Different Types of Hog Rings

Hog rings come in various shapes to cater to different applications and industries. Among the most common types are C Rings, D Rings, and Omega Rings, each offering unique features for specific fastening needs.

Hog rings come in various shapes to cater to different applications and industries. Among the most common types are C Rings, D Rings, and Omega Rings, each offering unique features for specific fastening needs.

C Rings

The C-rings are shaped like the letter “C” before installation and form a closed circular or oval shape when crimped. This type of ring is highly versatile and widely used for securing wire fencing, attaching upholstery to frames, and assembling animal cages.

It’s made from durable materials like galvanized, stainless steel, aluminum, or galfan. C-rings offer excellent corrosion resistance, making them suitable for both indoor and outdoor use. Theis strong grip and adaptability make them a popular choice for general fastening requirements.

D Rings

D-rings take on a “D” shape after closure, with one flat side and one rounded side, making them ideal for applications requiring stability and alignment, such as bedding or automotive upholstery. The flat side prevents twisting, ensuring a neat and secure finish when attaching straps or loops. Their streamlined design is particularly useful in tasks requiring precision and a polished appearance, offering both functionality and aesthetics.

Omega Rings

Omega rings are shaped like the “M” or the Greek letter Omega (Ω). It is designed for heavy-duty tasks, these rings are commonly used in industrial settings and fencing projects that require high load resistance. Their robust construction provides exceptional strength, making them suitable for securing thicker materials or objects under tension.

Comparison Chart for Different Types of Hog Rings

| Hog Ring Type | Shape Before Fastening | Closure Shape | Application Range |

|---|---|---|---|

| C Rings | C shaped | O shaped | General fastening |

| D Rings | C shaped | D shaped | Sensitive tasks |

| Omega Rings | M or Omega shaped | O shaped | Heavy-duty projects |

Applications of Hog Rings

Hog rings are versatile fasteners with widespread use across various industries due to their strength, durability, and ease of installation. Below are some of the most common applications of hog rings.

Hog rings are versatile fasteners with widespread use across various industries due to their strength, durability, and ease of installation. Below are some of the most common applications of hog rings.

1. Agriculture and Farming

- Securing animal cages, chicken coops, or enclosures.

- Attaching wire fencing.

- Repairing netting for crop protection or livestock containment.

2. Automotive Upholstery

- Fastening seat covers to the frames of car seats.

- Attaching fabric or leather to foam padding for a neat, professional finish.

- Used in assembling vehicle interiors that require durable connections.

3. Furniture and Upholstery

- Attaching springs, fabric, or cushioning to furniture frames.

- Repairing or reinforcing upholstery.

- Creating secure and seamless finishes for seats and cushions.

4. Construction and Fencing

- Installing chain-link fences by attaching the wire mesh to the framework.

- Securing insulation or materials in building projects.

- Repairing or assembling gabion baskets for landscaping or erosion control.

- Manufacturing the greenhouse structure.

5. Packaging and Shipping

- Closing sandbags, extra-large bags, or heavy-duty sacks.

- Bundling cables, hoses, or pipes for easy transport.

- Reinforcing packaging materials for industrial shipments.

6. Industrial and Manufacturing

- Joining wires or materials in production processes.

- Fastening components in heavy-duty machinery or equipment assembly.

- Securing materials under high tension in specialized industries.

How to Choose the Right Hog Ring for You Needs

Selecting the perfect hog ring for your projects requires considering several factors. Here’s a breakdown of the key aspects to help you make an informed decision.

Selecting the perfect hog ring for your projects requires considering several factors. Here’s a breakdown of the key aspects to help you make an informed decision.

1. Shape

Different shapes of hog rings for different usage. C-rings are ideal for general purpose fastening, such as fencing, cages, upholstery, sandbags, and upholstery; D-rings are best for bedding, furniture, automotive upholstery, and other sensitive tasks; Omega rings are designed for heavy-duty applications, offering exceptional strength for industrial applications.

2. Size

The size of the hog rings depends on the material being fastened. Users need to consider the outer crown, inner crown, leg length, wire size, and gauge to choose a suitable hog ring.

- Outer and Inner Crown: Choose a width that matches the workpiece thickness.

- Leg Length: Ensure the legs are long enough to wrap securely around the workpiece.

- Wire Size and Gauge: Thicker wire (lower gauge) is better for heavy-duty tasks, while thinner wire suits lightweight projects.

3. Material

Material is an important factor affecting the hog ring’s durability and resistance to wear. The common materials for hog rings are galvanized, stainless steel, and aluminum.

- Galvanized Steel: Ideal for outdoor applications due to its rust resistance.

- Stainless Steel: Best for high-moisture environments.

- Aluminum: Suitable for less demanding tasks because it’s lightweight and corrosion resistant.

4. Finish

Addition to material, the finish of hog rings also is a key point of enhancing the hog ring’s durability and suitability for specific environments. We list the common finishes and their suitable applications below.

- Plain Finish: Uncoated finish suitable for indoor or temporary applications where corrosion is not a concern.

- Galvanized Finish: Offers excellent rust resistance, making it ideal for outdoor use in moderate environments.

- Galfan Finish: Provides superior corrosion protection compared to standard galvanization, especially in harsh or marine environments.

- Zinc Coated: Economical and reliable, offering additional corrosion resistance for a variety of uses.

- Vinyl Coated: A flexible and smooth coating that provides insulation and basic corrosion resistance, commonly used for upholstery and lightweight outdoor applications.

- PVC Coated: A thicker, more rigid protective layer that offers superior durability and weather resistance, making I perfect for heavy-duty outdoor applications, such as fencing and industrial projects.

5. Tool Compatibility

Ensure the crown size, leg length, and gauge of each hog ring are compatible with the pliers you plan to use to avoid misuse or potential injury.

6. Application

When choosing a hog ring, it is essential to match it to your project’s specific requirements. Depending on the application, you may need to select different shape, material, or finish for the hog ring.

Hog Rings FAQ

We summarize and answer some common questions about hog rings below to help you make the most of these versatile fasteners in any project.

We summarize and answer some common questions about hog rings below to help you make the most of these versatile fasteners in any project.

What are the Common Sizes of Hog Rings?

Below are the common specifications of hog rings, including gauge, crown, width, and height, for each type.

Common Size Chart for C Ring

| Gauge | Crown | Heigh | Common Models |

|---|---|---|---|

| 16 Ga. | 16.80 mm | 10.40 mm | SR8, P7 |

| 16 Ga. | 16.80 mm | 9.00 mm | 516G100, C-17, SC660 |

| 16 Ga. | 23.60 mm | 12.00 mm | 16G110, SC-6, HR23, C-24 |

| 15 Ga. | 23.80 mm | 12.00 mm | 15G100N, SC-6, HR23, C-24 |

| 11 Ga. | 45.00 mm | 20.00 mm | 11RG40, CL50, C45 |

Common Size Chart for D Ring

| Gauge | Crown | Width | Heigh | Common Models |

|---|---|---|---|---|

| 15 Ga. | 29.80 mm | 1.80 mm | 14.00 mm | HR30,09DG25 |

| 15 Ga. | 17.80 mm | 1.80 mm | 9.5 mm | 515DG50, C-18 |

| 15 Ga. | 21.80 mm | 1.80 mm | 11.5 mm | HR22, HR60-22, SR15, C-22 |

Common Size Chart for Omega Ring

| Gauge | Crown | Heigh | Common Models |

|---|---|---|---|

| 14 Ga. | 18.00 mm | 8.00 mm | A16 |

| 14 Ga. | 18.00 mm | 9.30 mm | A18 |

| 14 Ga. | 20.00 mm | 11.00 mm | A20 |

How to Use Hog Rings?

Using hog rings effectively requires the right tools and proper technique. Follow these steps for secure fastening:

1. According to the above guide to select the appropriate hog ring for your project.

2. Place the open hog ring into the jaw of the plier.

3. Align the open ends of the hog ring around the workpiece to be fastened.

4. Squeeze the manual plier or activate the pneumatic tool to crimp the hog ring. This will close it into a secure loop, binding the workpiece together.

How to Remove Hog Rings? Can Hog Rings Be Reused?

Removing hog rings safely and efficiently is crucial to prevent damaging the workpieces they secure.

1. Identify the ends of the hog ring to determine where to apply pressure or cut for easier removal.

2. If the hog ring is loosely crimped, use a flat-head screwdriver or plier to pry the ends apart carefully. For tightly secured hog rings, use diagonal cutters to snip through the metal.

3. After loosening or cutting, gently pull the hog ring away from the workpiece.

4. Discard removed hog ring properly to avoid accidents or potential misuse.

Once hog rings are crimped, their structural integrity is compromised, making them unsuitable for reinstallation. Reusing hog rings can result in loose or unreliable fastening, which may compromise the safety and durability of the project.

Conclusion

Hog rings are a powerful yet simple fastening solution that excels in a wide range of applications. Their adaptability, strength, and ease of use make them a top choice for both professionals and DIY enthusiasts. From lightweight tasks like securing upholstery to heavy-duty applications such as industrial fencing, hog rings provide unmatched reliability. By understanding the different types, sizes, materials, and finishes, you can confidently select the right hog ring for your project and achieve durable, long-lasting results.

At VIM, we offer a variety of C-rings, D-rings, and Omega rings in different sizes and materials to suit your needs. If you would like to learn more or inquire about our hog rings, please feel free to contact us at your convenience.

Article Classification

Recent Articles

- 5 Essential Checklist for Choosing Appropriate Flooring Nails

- Every Corrugated Fastener You Want—All Here in One Comprehensive Guide

- The 4 Carton Staples Issues Ruining Your Packaging—Solved in Minutes

- 5 Reasons Why VIM Concrete T Nails Deliver Unmatched Grip and Durability

- The Hidden Force in Every Staple: 9 Point Types That Make Fastening Last